Ensuring the longevity and efficiency of an automobile’s transmission system involves attention to the minutest details, including the often overlooked yet crucial aspect of transmission pan torque specs.

The transmission pan, a vital component of the gearbox, serves as a reservoir for transmission fluid, safeguarding against friction and wear. Properly securing this pan is essential to prevent leaks and maintain optimal performance.

Understanding the significance of adhering to specific torque requirements for the transmission pan bolts is fundamental for both maintenance and repair procedures.

This article delves into the significance of transmission pan torque specs, offering comprehensive insights into why these seemingly small details hold significant implications for the overall health and functionality of a vehicle’s transmission system.

By exploring the correct torque specifications and their impact, this piece aims to underscore the importance of this often underestimated facet in ensuring a well-maintained and smoothly operating transmission system.

What is Torque, and What Makes It Essential?

Torque is a fundamental concept in the realm of mechanics, defining the rotational force applied to an object around an axis. In the context of automobiles, torque is pivotal in determining the engine’s ability to generate power, enabling the vehicle to move forward. It is essentially the force that propels a car, creating the necessary rotation for the wheels.

Understanding torque is crucial because it directly influences a vehicle’s performance. The engine produces torque, which is then transmitted through the transmission system to the wheels.

The amount of torque generated affects the car’s acceleration, towing capacity, and overall power delivery. Insufficient torque may lead to sluggish acceleration or struggles in climbing steep inclines, while excessive torque could potentially strain the engine or transmission system.

This force’s significance lies in maintaining a delicate balance – too little, and the vehicle lacks power; too much, and it risks damaging essential components. Therefore, comprehending torque and its optimal application is vital in ensuring a vehicle’s efficient and safe operation.

Mechanics and engineers meticulously calculate and set torque specifications for various components, such as transmission pans, to maintain the delicate equilibrium necessary for a vehicle’s optimal functioning and longevity.

Explanation Of Transmission Pan Torque Specs

The torque specifications for a transmission pan play a crucial role in maintaining a vehicle’s transmission system. Often an overlooked detail during maintenance or repairs, the torque applied to the transmission pan bolts is integral to ensuring the proper sealing and functioning of the transmission.

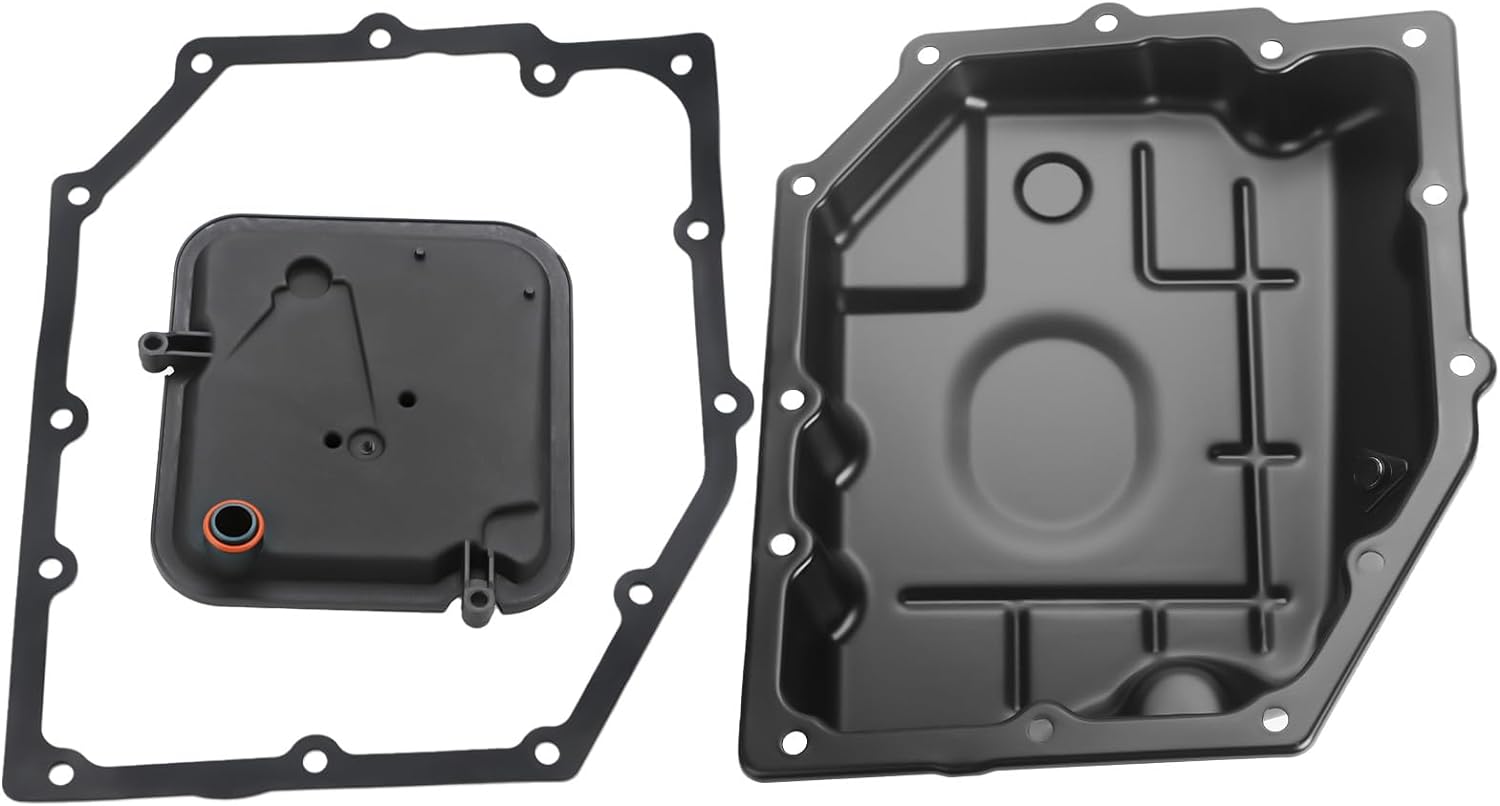

Transmission pans are essential components of a vehicle’s gearbox. They house transmission fluid, which lubricates the gears and components inside. The proper sealing of the pan is vital to prevent leaks and preserve the integrity of the transmission system. This is where the importance of correctly applying torque to the pan’s bolts becomes evident.

Torque specifications refer to the specific measurement of rotational force needed to tighten the bolts that secure the transmission pan in place. These specifications are usually provided by the vehicle’s manufacturer and are crucial to follow during any transmission-related work. The correct torque ensures a uniform and secure seal, preventing leaks that could lead to fluid loss and potential damage to the transmission system.

Over-tightening or under-tightening the bolts can lead to various issues. Under-tightening might result in leaks due to an inadequate seal, while over-tightening could warp or crack the pan, leading to similar leakage problems or even potentially damaging the threads on the bolts or the transmission casing.

Each vehicle model and transmission system may have different torque specifications, so it’s essential to consult the manufacturer’s guidelines or repair manual. Typically, torque values are specified in inch-pounds or foot-pounds, and using a torque wrench calibrated to the recommended settings is crucial for accuracy.

When working with transmission pan torque specs, it’s essential to follow a specific sequence for tightening the bolts, usually in a crisscross pattern. This technique ensures an even distribution of force across the pan, helping to achieve a proper seal and preventing leaks.

The significance of understanding and adhering to these torque specifications cannot be overstated. Failure to follow these guidelines might result in fluid leaks, which not only lead to transmission damage but can also affect the vehicle’s overall performance and safety.

In essence, the correct transmission pan torque specs are essential for maintaining the health and efficiency of a vehicle’s transmission system. They contribute significantly to preventing leaks, ensuring proper lubrication, and ultimately, sustaining the longevity and functionality of the transmission, underscoring the importance of this seemingly small yet critical detail in automotive maintenance.

Related Post: Why Does The Transmission Downshifting Hard While Slowing Down?

What Are the Transmission Pan Torque Specs Specifications for Specific Vehicle Models?

The torque specifications for an oil pan, typically falling within the range of 10-20 lb-ft, serve as fundamental guidelines for securing this essential component of a vehicle’s engine. However, these figures can notably differ based on the specific make, model, and engine type of the vehicle. It is imperative to reference the manufacturer’s suggestions or reliable technical resources to obtain the precise torque value required for your oil pan.

While there are generalized torque guidelines, adhering to the specific torque specifications provided by your vehicle’s manufacturer is of utmost importance. These specifications are not universal across all vehicles but are meticulously determined through extensive testing to ensure optimal performance and durability of components, such as transmission pans.

The process of determining torque specifications involves comprehensive testing by vehicle manufacturers to ascertain the ideal torque values for individual components. This meticulous approach ensures that each vehicle’s unique requirements are met, encompassing factors such as the make, model, and transmission type.

Discovering the specific torque specifications for your vehicle necessitates referring to the owner’s manual or accessing the manufacturer’s official website. Additionally, online automotive forums and technical resources offer invaluable insights and recommendations based on practical experiences, providing additional guidance for torque values and practical application advice. These resources offer real-world expertise and opinions, helping vehicle owners and technicians make more informed decisions when working on their vehicles.

Below are some instances of torque specifications for well-known vehicle models:

- 4l60e transmission pan torque specs: Typically 12-13 lb-ft

- 4l80e transmission pan torque specs: Generally around 18 lb-ft

- 62te transmission pan torque specs: Usually 50-80 lb-in

- Ford transmission pan torque specs: Can vary by model, such as the Ford Focus requiring around 9 lb-ft

- 6l80 transmission pan torque specs: Commonly 18 lb-ft

- 6r140 transmission pan torque specs: Typically 13-15 lb-ft

- 68rfe transmission pan torque specs: Usually 22-24 lb-ft

- 6l90 transmission pan torque specs: Commonly 18 lb-ft

- 6r80 transmission pan torque specs: Typically around 18 lb-ft

- 8l90 transmission pan torque specs: Usually around 10 lb-ft

- th350 transmission pan torque specs: Typically around 13-15 lb-ft

- 2001 Dodge Ram 1500 transmission pan torque specs: Often around 10-12 lb-ft

- 2003 Ford Ranger transmission pan torque specs: Typically around 10-12 lb-ft

- 2007 Mazda 3 transmission pan torque specs: Often around 10 lb-ft

- 2008 Nissan Altima transmission pan torque specs: Typically around 8-9 lb-ft

- 2009 Nissan Altima transmission pan torque specs: Often around 8-9 lb-ft

- 2010 F150 transmission pan torque specs: Generally around 10-12 lb-ft

- 2011 Nissan Altima transmission pan torque specs: Often around 8-9 lb-ft

- 2012 Ram 1500 transmission pan torque specs: Generally around 10-12 lb-ft

- 2013 Dodge Grand Caravan transmission pan torque specs: Typically around 10-12 lb-ft

Please note that these figures are presented as illustrations, and it’s crucial to refer to the official documentation for the torque specifications specific to your vehicle.

Can you excessively tighten a transmission pan?

Certainly, it’s entirely possible to overtighten a transmission pan. Applying excessive torque while securing the pan can have several adverse effects on the integrity of the transmission system.

The repercussions of over-tightening can include stripped threads, causing damage to the pan itself or the gasket, potentially resulting in leaks and subsequent transmission problems.

This can create a domino effect, impacting the smooth functioning of the transmission components and leading to increased wear and tear.

Adhering to the torque values recommended by the manufacturer is crucial to prevent such issues. Following the prescribed torque specifications is essential to avoid overtightening.

Employing a calibrated torque wrench helps in achieving the precise level of tightness without the risk of applying excessive force.

This precision ensures that the transmission pan is adequately secured without causing damage to the threads, pan, or gasket, ultimately maintaining the proper sealing and functionality of the transmission system.

Therefore, the key lies in following the manufacturer’s torque specifications and using the appropriate tools to secure the transmission pan effectively.

Also Read: What Are The Symptoms of Loose Strut Nut: Stay Informed!

What are the Proper Torquing Techniques for Transmission Pans?

Knowing the significance of torque specifications and the methods to obtain them, let’s delve into the proper technique for torquing transmission pans. A systematic, step-by-step approach is vital for ensuring the correct application of torque to achieve an effective seal and maintain the transmission’s integrity.

Step 1: Initiating with a Clean Surface

The first step involves meticulously cleaning the mating surfaces of both the transmission housing and the pan. This thorough cleansing ensures an optimal and secure seal once the transmission pan is reassembled.

Step 2: Preparing the Pan and Gasket

Either placing a new gasket or applying a suitable sealant to the transmission pan is the next essential step in the process. The goal here is to ensure a reliable and leak-proof connection between the pan and the transmission housing.

Step 3: Proper Alignment and Hand-Tightening

After applying the gasket or sealant, the pan must be aligned meticulously with the transmission housing. Hand-tightening the bolts or screws is the initial phase of securing the pan in place.

Step 4: Using the Torque Wrench Methodically

Employing a torque wrench is crucial for achieving the specified torque value. It’s recommended to follow a cross-pattern sequence to gradually tighten the fasteners. This approach helps in ensuring an even distribution of force across the pan, thus minimizing the risk of leaks or damage.

Step 5: Reiterating the Torque Application

The process of using the torque wrench should be repeated until the desired torque value is achieved. The application of torque requires attention to detail and the recommended sequence to achieve an optimal and secure seal.

Utilizing a Torque Wrench Effectively

To ensure the accurate application of torque, it is essential to set the torque wrench to the specified torque value. Holding the handle firmly and applying a steady and gradual force is key to achieving the desired torque. Avoiding sudden or jerky movements is necessary to prevent inaccurate torque readings.

Tips for Precision in Torque Application

The use of a high-quality torque wrench that is regularly calibrated is essential for accurate readings. Avoiding extensions or adaptors during the torquing process is recommended, as they might affect the accuracy of torque application. Following the recommended torque sequence is crucial to evenly distribute the force. Taking intermittent breaks during the torqueing process allows the gasket or sealant to settle and ensures a more effective seal.

How does one calculate torque specifications?

Determining torque specifications is a multi-faceted process involving various factors such as the material being fastened, desired clamping force, and thread specifics. Here’s a comprehensive outline for calculating torque specs:

-

Evaluate Clamping Force Requirements

Calculating the necessary clamping force is crucial and relies on the application and the material being fastened. This information can often be obtained through engineering specifications, design guidelines, or industry standards. These resources help in establishing the desired clamping force for a particular application.

-

Identify Thread Type and Size

Understanding the thread type (metric or imperial) and the thread size (measured in diameter or pitch) of the fastener is essential. This information serves as a basis for determining the appropriate torque specifications.

-

Consult Torque Charts or Guidelines

Torque charts are valuable resources that offer recommended torque values. They factor in thread size, material, and desired clamping force. These charts are commonly available from fastener manufacturers or within engineering references. By cross-referencing the thread size and material, one can determine the corresponding torque range.

-

Consider Additional Influencing Factors

Other factors may play a role in defining the torque specification. Conditions like the presence of lubricants, the state of the thread, type of fastener (bolts, screws), and any specific recommendations provided by the manufacturer should be taken into account.

-

Application of Torque Wrench

Utilize a calibrated torque wrench to apply the calculated torque value to the fastener. Gradually increasing the force is crucial, ensuring that the desired torque value is reached without exceeding the recommended maximum torque.

It’s important to emphasize that torque specifications can vary significantly based on distinct applications and requirements. Always refer to the manufacturer’s guidelines, engineering specifications, or consult professionals, especially in critical or safety-critical applications, to ensure accurate and appropriate torque calculations. This ensures that the fasteners are properly secured while mitigating any risks associated with incorrect torque application.

What is the proper torque for oil pan bolts?

The proper torque for oil pan bolts is a critical consideration in maintaining the integrity and reliability of an engine. The specific torque required for oil pan bolts can vary depending on the make and model of the vehicle. The torque value is usually provided by the manufacturer in the vehicle’s service manual or technical specifications.

It’s imperative to adhere to the manufacturer’s recommended torque specifications when tightening the oil pan bolts. Over-tightening can result in damaging the oil pan or the threads, causing leaks, warping the pan, or compromising the sealing surface. Conversely, under-tightening may lead to inadequate sealing, causing oil leaks and potential damage to the engine due to oil loss.

The torque specifications are typically measured in pound-feet (lb-ft) or inch-pounds (in-lb) and are crucial to maintain the appropriate pressure needed to seal the oil pan without causing damage. Utilizing a torque wrench set to the recommended torque value is essential to achieve the precise tightness required for the oil pan bolts.

Before tightening the oil pan bolts, it’s important to clean the mating surfaces thoroughly and ensure that a new gasket or sealant is appropriately applied. Following the manufacturer’s recommended torque sequence, usually in a crisscross or star pattern, ensures even distribution of pressure and facilitates a proper seal.

How tight should transmission drain plug be?

The recommended tightness for a transmission drain plug is typically outlined in the manufacturer’s guidelines. Using a calibrated torque wrench, gradually tighten the plug until it reaches the specified torque value.

The torque specifications vary by vehicle model and are crucial for ensuring an effective seal without overtightening, which can damage the threads or the transmission casing. Optimal torque application prevents leaks, ensuring the drain plug is secure but not excessively tightened, thus maintaining the integrity of the transmission system.

Consulting the vehicle’s manual or manufacturer’s recommendations is essential to determine the precise torque value for the transmission drain plug.

FAQs About Transmission Pan Torque Specs

What torque should I use for screws?

The specific torque for screws can vary based on the application and material. Always refer to the manufacturer’s specifications or engineering guidelines for the recommended torque values.

Do you need a torque wrench for the oil pan?

Utilizing a torque wrench is crucial for achieving the precise torque value required when tightening oil pan bolts. It helps prevent over-tightening or under-tightening, ensuring the proper seal without damaging the components.

What is the torque on a 6mm oil pan bolt?

The torque value for a 6mm oil pan bolt typically varies by vehicle model. Consult the manufacturer’s manual or technical specifications for the precise torque value recommended for the specific vehicle’s oil pan bolt size.

Conclusion

Adhering to precise torque specifications is paramount in maintaining the integrity and functionality of a vehicle’s essential components, such as oil pans and transmission systems. The torque values specified by manufacturers are not mere guidelines but crucial parameters that prevent both under-tightening, which may cause leaks, and over-tightening, which can lead to damaging the components. Utilizing calibrated torque wrenches, following recommended sequences, and referencing manufacturer guidelines are fundamental practices in ensuring proper torque application. Ultimately, meticulous attention to torque specifications safeguards against potential damage, promotes longevity, and ensures the seamless operation of a vehicle’s critical systems.