Engine troubles manifest in distinct sounds, notably, rod knocks and lifter ticks. Understanding these noises is crucial for automotive health. A rod knock indicates a serious issue, akin to a hammer hitting metal, arising from connecting rod bearing problems. Lifter ticks produce consistent ticking, resembling a sewing machine, originating from valve lifters and oil circulation. Distinguishing between them is challenging, but crucial: rod knocks are louder and can intensify with RPM, while lifter ticks are quieter and may diminish as the engine warms up. Correct identification, professional diagnosis, and appropriate maintenance are key to safeguarding an engine’s health and longevity.

Also Read: P0113 Dodge: Addressing High Input In Intake Air Temperature Sensor 1 Circuit

What is a Rod Knock?

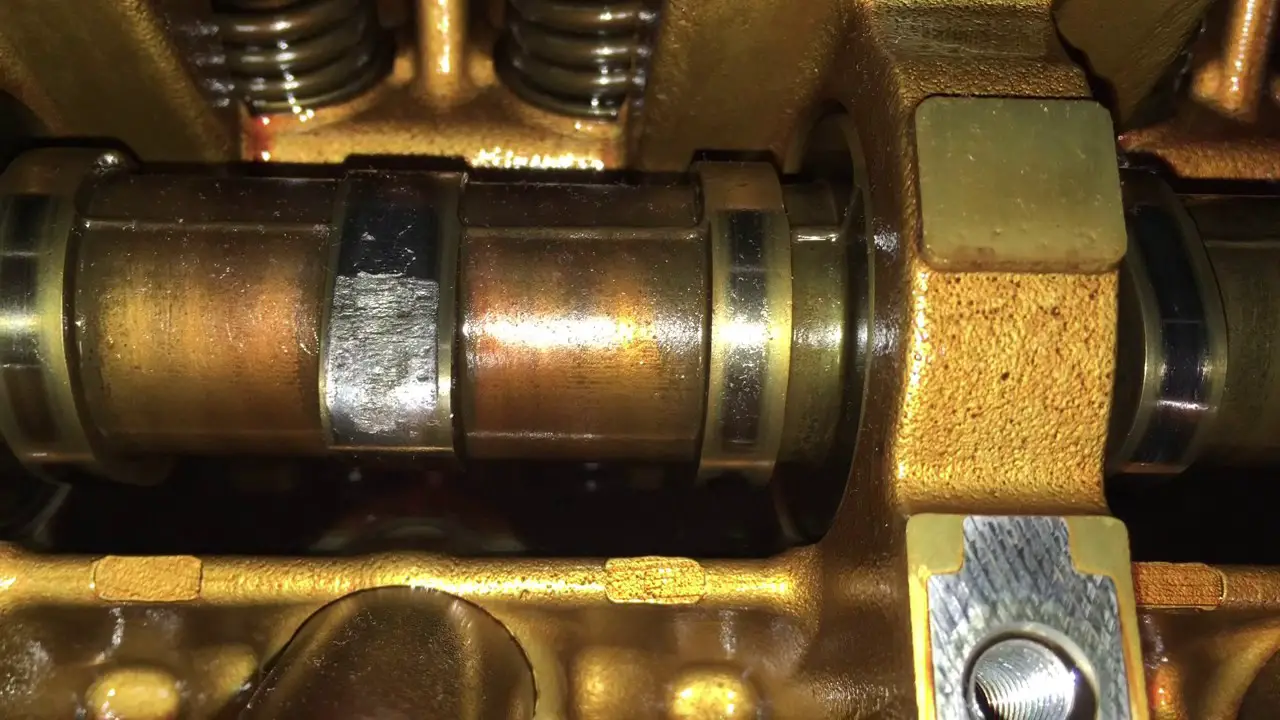

A rod knock, a distinct repetitive metallic tapping or knocking noise, emanates from the internal workings of an engine. This sound, resembling the force of a hammer striking metal, serves as a forewarning of a significant internal engine complication. The primary culprit behind this disconcerting noise is commonly traced to problems associated with the connecting rod bearings.

These bearings, vital in the engine’s functionality, tend to wear out over time due to factors such as insufficient lubrication, high mileage, or poor maintenance. The persistent knocking sound often grows louder as the problem exacerbates, signifying potential damage and requiring immediate attention. Ignoring this issue might lead to severe engine damage, emphasizing the critical importance of prompt diagnosis and repair to prevent catastrophic engine failure.

What is Lifter Ticks?

Lifter ticks manifest as a steady and consistent ticking noise, reminiscent of the rhythmic sounds produced by a sewing machine. These audible vibrations stem from the hydraulic valve lifters, also known as tappets, nestled within the engine. These crucial components operate in synchronization with the engine’s valve train, regulating the movement of the valves.

However, when these lifters encounter a scarcity of lubricating oil, especially at the top of the engine, they become prone to creating this distinctive ticking noise. The lack of a proper oil supply hampers the smooth movement of the lifters, leading to their intermittent ticking. This issue often arises due to oil-related problems, such as oil degradation, insufficient oil levels, or blockages within the oil passages.

Resolving lifter ticks commonly involves rectifying oil circulation issues, such as changing the oil filter, using high-quality engine oil, or incorporating oil additives to enhance lubrication and mitigate the ticking sound. Ignoring lifter ticks might not immediately damage the engine, but it can point to underlying problems that, if left unattended, may lead to increased wear and potential damage to critical engine components. Hence, identifying and addressing lifter ticks promptly through proper maintenance and potential repairs is vital to ensure the engine’s optimal performance and longevity.

Rod Knock vs. Lifter Tick

When it comes to engine issues, distinguishing between rod knocks and lifter ticks is pivotal for effective troubleshooting and maintenance. Understanding the fundamental differences between these sounds, their origins, and their implications is crucial in diagnosing and addressing the underlying problems.

Characteristics and Sounds

- Rod Knock

A rod knock is characterized by a repetitive, pronounced metallic tapping or knocking noise, resembling a hammer striking metal. It typically emanates from the bottom end of the engine and often grows louder with increased RPM. The root cause of this distinct sound is usually traced back to problems with the connecting rod bearings, crucial components that aid in the smooth movement of the engine’s internal parts.

- Lifter Tick

In contrast, lifter ticks manifest as a consistent and relatively softer ticking noise, reminiscent of a sewing machine’s rhythmic operation. This noise primarily originates from the hydraulic valve lifters or tappets situated at the top of the engine. Lifter ticks occur due to inadequate oil reaching the upper part of the engine, impacting the proper movement of these vital engine components.

Diagnosis and Identification

- Distinguishing Factors

One of the key factors in differentiating these sounds lies in their volume and location. Rod knocks are generally louder, more prominent, and primarily heard near the bottom end of the engine. As the RPM increases, the knocking sound becomes more evident. Lifter ticks, on the other hand, are softer and originate from the upper part of the engine. They might decrease in intensity as the engine warms up.

Testing and Observation

Identifying these noises often involves a combination of methods. Careful listening and observing the characteristics of the sound while varying the engine’s RPM can aid in distinguishing between a rod knock and a lifter tick. Diagnostic tools, such as stethoscopes or noise-detecting devices, can be used by professional mechanics to precisely pinpoint the source of the noise.

Causes and Implications

- Rod Knock Causes

Rod knocks primarily occur due to wear and tear of the connecting rod bearings. Factors like insufficient lubrication, high mileage, poor maintenance, or debris in the oil can lead to bearing damage. Ignoring rod knocks can result in catastrophic engine failure if the problem remains unaddressed, leading to extensive damage to the engine’s internal components.

- Lifter Tick Causes

Lifter ticks commonly stem from inadequate oil reaching the top of the engine, affecting the smooth movement of the hydraulic valve lifters. This issue is often related to oil circulation problems such as degraded oil, low oil levels, or clogs in oil passages. While lifter ticks themselves might not immediately harm the engine, they signal underlying issues that, if neglected, could lead to increased wear on the engine components.

Solutions and Repair

- Rod Knock Resolutions

Resolving rod knocks typically requires more extensive repairs. This often involves disassembling the engine to replace the damaged connecting rod bearings. Professional mechanical intervention is often necessary for this kind of repair.

- Lifter Tick Solutions

Addressing lifter ticks often involves rectifying oil circulation issues. Actions such as changing the oil filter, using high-quality engine oil, or employing oil additives can help improve lubrication, alleviating the ticking sound caused by the affected hydraulic valve lifters.

Preventive Measures

Regular maintenance, including adhering to manufacturer-recommended service intervals and timely oil changes, plays a pivotal role in preventing both rod knocks and lifter ticks. Ensuring proper lubrication by using high-quality oil and maintaining adequate oil levels helps in mitigating the risk of developing these engine issues.

Distinguishing between rod knocks and lifter ticks is crucial for maintaining a healthy engine. These distinct sounds, although similar in their audible nature, signify different underlying problems within the engine. Prompt identification, professional diagnosis, and appropriate maintenance are vital to safeguard the engine’s health and longevity. Resolving these issues in a timely manner not only prevents potential damage but also ensures the smooth operation and extended lifespan of the engine.

How Can You Tell a Rod Knock from a Lifter Tick?

Distinguishing between a rod knock and a lifter tick can be challenging due to their similar audible nature, yet key distinctions in their characteristics exist. A rod knock typically resonates as a louder and more prominent noise, becoming increasingly audible and forceful with higher engine RPM.

This distinctive sound, resembling a hammer striking metal, often emanates from the bottom end of the engine and remains consistent regardless of the engine’s temperature. Conversely, lifter ticks present as softer and less pronounced ticking noises, akin to a sewing machine, coming from the top of the engine.

These ticks may decrease in intensity or even diminish as the engine warms up, signifying their link to oil circulation and hydraulic valve lifter issues. The varying intensities, locations, and the relationship of these sounds to engine RPM serve as key indicators in discerning between a rod knock and a lifter tick during diagnostic assessments.

What Else Sounds Like a Lifter Tick?

While lifter ticks present as a distinctive ticking noise within an engine, similar sounds can arise from various other issues, making the precise identification of the noise’s origin crucial for accurate troubleshooting.

- Timing Chain Issues

Problems with the timing chain can generate noises akin to lifter ticks. A timing chain that’s worn, loose, or misaligned can produce a rattling or tapping sound that might resemble lifter ticks. Proper diagnosis involves checking the timing chain’s tension, alignment, and condition to differentiate this noise from lifter ticks.

- Low Oil Pressure

Inadequate oil pressure within the engine can lead to lifter-like sounds. Insufficient oil reaching critical engine components, including the hydraulic valve lifters, might cause them to operate less smoothly, resulting in ticking noises. Monitoring oil levels and pressure, along with ensuring proper oil circulation, is crucial in differentiating between low oil pressure-related sounds and lifter ticks.

- Faulty Water Pump

A malfunctioning water pump can also create noises similar to lifter ticks. A failing water pump might produce a continuous ticking or rattling sound, especially as it struggles to function properly. Distinguishing this noise from lifter ticks involves examining the water pump’s functionality and assessing whether the noise correlates with its operation.

Accurate troubleshooting involves a methodical approach. Mechanics typically perform various tests and inspections to identify the exact source of the noise. This often includes using diagnostic tools, checking specific components, and monitoring the engine’s performance under different conditions to pinpoint the origin of the noise accurately.

Addressing such noises promptly is crucial. While lifter ticks themselves might not inflict immediate harm on the engine, these similar-sounding issues—like problems with the timing chain, low oil pressure, or a faulty water pump—might point to underlying concerns. Ignoring these concerns can lead to increased wear on engine components and potential damage, emphasizing the importance of prompt diagnosis and appropriate action to maintain an engine’s optimal performance and longevity.

Can Lifter Tick Damage Your Engine?

Lifter ticks, while seemingly innocuous in their initial presentation, can indicate underlying issues that, if disregarded, may potentially lead to severe engine damage. Although the ticking noise, by itself, might not directly cause harm to the engine, it serves as a warning sign of more significant problems, particularly related to oil circulation and lubrication.

The hydraulic valve lifters, integral components within the engine, rely on a continuous supply of lubricating oil to operate smoothly. When lifter ticks manifest, it is often due to an insufficiency of oil reaching these components. This can result from various factors, including degraded oil, inadequate oil levels, oil contamination, or blockages within the oil passages.

While the immediate impact of lifter ticks on the engine might seem minimal, over time, the compromised lubrication caused by oil flow problems can result in increased wear and tear on engine components. The lack of proper lubrication can lead to the lifters functioning less efficiently, causing friction and wear within the engine.

This increased wear due to inadequate lubrication, if prolonged, can have detrimental effects on the engine’s longevity and performance. The continuous friction between the components can lead to excessive heat and damage to the critical parts of the engine, potentially resulting in severe and costly repairs. Over time, if left unattended, this wear and tear can impact the overall efficiency of the engine, affecting its performance and, in severe cases, leading to engine failure.

Prompt attention to the issue of lifter ticks is vital in preventing further damage to the engine. Addressing the underlying problems related to oil circulation, such as changing the oil filter, using high-quality oil, and ensuring proper oil levels, can significantly mitigate the ticking sound. Employing oil additives designed to enhance lubrication might also aid in rectifying the issue.

Regular maintenance, including timely oil changes and adhering to manufacturer-recommended service intervals, is crucial in preventing and addressing potential oil-related issues. Regular checks on oil levels and quality, along with the early identification and resolution of any abnormal engine noises, including lifter ticks, are fundamental in preserving the engine’s health and longevity.

How Do I Know If My Car Has a Rod Knock?

Identifying a rod knock in your car involves careful observation and attention to specific indicators that distinguish this issue from other engine abnormalities. A rod knock is a distinctive noise, often signaling an internal engine problem that necessitates immediate attention.

Auditory Cues

A rod knock is characterized by a repetitive, loud metallic tapping or knocking noise that emanates from the engine. This distinct sound typically resonates near the bottom end of the engine and resembles the forceful striking of metal by a hammer. The noise becomes more pronounced and evident with increased RPM, especially during acceleration. When the engine revs, the knocking sound often intensifies, becoming more noticeable.

Oil Pressure

Coupled with the distinct noise, a reduction in oil pressure might coincide with a rod knock issue. A decrease in oil pressure, detected through the vehicle’s dashboard warning indicators or through specific gauges, could be an additional sign of trouble. Low oil pressure might signify that the engine is not receiving adequate lubrication, exacerbating the rod knock issue.

Causes for Concern

The presence of a rod knock is an alarming sign as it typically indicates a significant internal engine problem, commonly related to wear or damage in the connecting rod bearings. Factors contributing to this problem could include insufficient lubrication, high mileage, poor maintenance, or the presence of debris in the oil, all of which can cause damage to the bearings and result in the audible knocking noise.

Differentiating from Similar Noises

It’s essential to differentiate a rod knock from other engine noises that might sound similar, such as piston slap or a loose pulley. A piston slap is a sharp metallic sound that usually diminishes as the engine warms up, unlike the persistent knocking of a rod knock. A loose pulley might produce a rattling sound that usually correlates with the engine’s RPM and the speed of the vehicle.

Addressing the Issue

Immediate attention to a rod knock is crucial to prevent further damage to the engine. Ignoring a rod knock can lead to catastrophic engine failure if the problem remains unresolved. Resolving this issue typically requires extensive repairs, including possible engine disassembly to replace the damaged connecting rod bearings.

Diagnosis and Repair

Accurate diagnosis plays a pivotal role in effectively addressing both rod knocks and lifter ticks, requiring professional insight or the utilization of specialized diagnostic tools to precisely identify the issue. Consulting a seasoned mechanic with expertise in engine diagnostics or employing diagnostic equipment helps in pinpointing the source of the problem with greater accuracy.

For lifter ticks, the resolution often revolves around ensuring proper lubrication of the engine components. This can involve the use of oil additives designed to enhance the oil’s lubricating properties or opting for an oil change with a high-quality lubricant. Addressing oil flow problems generally rectifies the issue, allowing the hydraulic valve lifters to operate smoothly and reducing the ticking noise.

In contrast, resolving rod knocks typically demands more extensive measures. This may involve significant engine repairs, potentially necessitating the disassembly of the engine to replace the damaged connecting rod bearings. The complexity of repairing rod knocks often requires meticulous attention and expertise, as well as the replacement of worn or damaged components to restore the engine’s proper functionality.

While addressing lifter ticks might involve simpler solutions centered around improving lubrication, resolving rod knocks can be a more labor-intensive and intricate process. The nature of the repairs often depends on the severity of the damage and may necessitate a thorough examination of the engine by a qualified professional to determine the most appropriate course of action.

Preventive Measures

Preventive measures play a crucial role in averting engine issues such as rod knocks and lifter ticks. Implementing a comprehensive maintenance regimen and adhering to specific practices significantly reduces the likelihood of encountering these problems.

-

Regular Maintenance

Regular maintenance serves as the cornerstone of preventive care. Consistent inspection and servicing of the vehicle, including routine checks on the engine’s health, aid in the early detection of potential issues. This includes examining for any signs of oil degradation, monitoring oil levels, and assessing overall engine performance.

-

Timely Oil Changes

Regular and timely oil changes are paramount in sustaining a healthy engine. Fresh, high-quality oil helps in maintaining proper lubrication, preventing wear on engine components, and reducing the risk of both rod knocks and lifter ticks. Routine oil changes as recommended by the vehicle manufacturer ensure that the engine operates smoothly and efficiently.

-

Using High-Quality Oil

Opting for high-quality engine oil is fundamental to engine health. Quality oil not only lubricates the engine but also contains essential additives that aid in reducing friction and maintaining the engine’s cleanliness. These additives also contribute to the longevity of engine components, minimizing the risk of wear and tear that could lead to issues like rod knocks and lifter ticks.

-

Manufacturer-Recommended Service Intervals

Adhering to the service intervals outlined by the vehicle manufacturer is crucial. These intervals are strategically designed to address necessary maintenance tasks, including oil changes, filter replacements, and overall inspections, ensuring that the engine operates optimally and minimizing the risk of potential issues.

Conclusion: Rod Knock vs Lifter Tick

Distinguishing between rod knock and lifter tick is imperative for maintaining a healthy engine. These distinct sounds, although similar, signify different underlying problems within the engine. Being attentive to these noises and promptly addressing them through professional diagnosis and appropriate maintenance can help safeguard your vehicle’s engine health and longevity.