When maneuvering your vehicle, the occurrence of noise from newly installed struts might trigger concern. The culprit behind this nuisance could stem from a range of factors such as substandard installation practices, insufficient break-in periods, poor-quality strut components, or even misalignment issues. Resolving these concerns is pivotal to ensuring optimal performance and a peaceful driving experience.

Your car’s suspension, a complex network responsible for ride comfort and handling, heavily relies on the health of its struts. These components act as silent guardians, absorbing jolts and maintaining steadiness, thereby amplifying your control over steering. However, encountering disruptive noises emanating from these vital parts can mar the driving experience, especially during turns.

In the following discourse, we’ll unravel the mysteries behind these disturbances and offer invaluable insights to rectify and address the persistent issue, ensuring your driving encounters remain tranquil and trouble-free.

How should new struts sound?

New struts, when functioning optimally, should ideally operate stealthily, akin to the serenity of a seamless ballet performance. When the vehicle is in motion, especially when navigating turns or encountering bumps on the road, well-installed and properly functioning struts operate without any audible cues. These silent sentinels, nestled within the suspension system, work harmoniously, efficiently absorbing shocks and undulations without a whisper or a groan.

The absence of noise from new struts signifies their smooth operation, quietly mitigating the impact of uneven terrain or undulations on your vehicle. A well-fitted, quality strut set, properly aligned and with an adequate break-in period, complements the vehicle’s movements, rendering a tranquil and composed ride.

However, disturbances in this symphony of silence can occur when struts produce noticeable sounds, such as clunks, squeaks, or rattles. These noises might indicate underlying issues—possibly due to poor installation, misalignment, or inferior quality components. Addressing such disturbances promptly ensures the restoration of the intended silent operation, preserving not just tranquility but also the efficiency and safety of your vehicle’s suspension system.

What are Struts and what are their function?

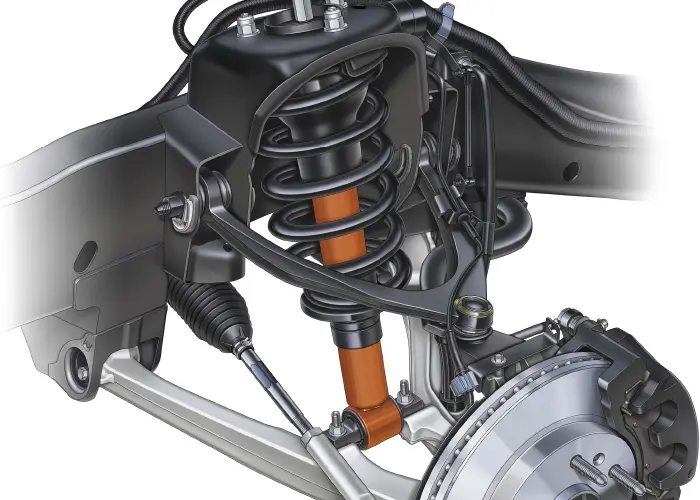

Struts serve as vital components within a vehicle’s suspension system, playing a pivotal role in maintaining stability, enhancing control, and ensuring a comfortable ride. Comprehending their function and importance can significantly contribute to better vehicle maintenance and an improved driving experience.

Key functions of struts

-

Structural Support and Weight Bearing

Struts are essential for providing structural support within the suspension system, carrying the weight of the vehicle. They serve as a mounting point for the coil spring, which assists in maintaining the vehicle’s ride height and overall structural integrity. By managing the vehicle’s weight, struts aid in a smoother and more controlled driving experience.

-

Dampening Oscillations and Impact Absorption

Their primary function involves absorbing the impact generated from uneven road surfaces, regulating the vehicle’s movement, and controlling the oscillations and bouncing motions. Struts compress and rebound within a specific range to minimize excessive bouncing, offering a more comfortable ride while enhancing handling and control, particularly during steering and braking.

-

Ensuring Tire Traction and Stability

Maintaining consistent contact between the tires and the road surface is crucial for maximizing tire traction. Struts play a pivotal role in keeping the tires in contact with the ground, ensuring better grip, stability, and improved handling, especially in challenging road conditions. This feature significantly contributes to safer driving experiences.

-

Signs and Maintenance

Recognizing signs of potential issues with struts is imperative for timely maintenance. Unusual indicators like uneven tire wear, excessive bouncing or dipping during acceleration or braking, a rough ride, or visible damage or leakage around the strut assembly might signal the need for inspection or replacement. Moreover, atypical noises such as clunks, squeaks, or rattles are warning signs for potential strut problems.

-

Ensuring Optimal Performance

To maintain their efficiency and longevity, it is crucial to invest in high-quality struts, ensure proper alignment during installation, and allow for a break-in period. Seeking advice from professional mechanics or installers and conducting regular inspections can further ensure optimal performance and durability of the struts, contributing to a smooth, safe, and enjoyable driving experience.

Also Read: Why is my car blowing white smoke but not overheating? Why?

What are the Possible Causes of Noise from New Struts?

-

Lack of Proper Break-in Period

When new struts are installed, they require a break-in period to settle and adapt to their working conditions. The break-in process allows the components to adjust and function optimally. Without this break-in period, the struts may produce noise due to initial friction or minor misalignments that need time to settle. It’s crucial to adhere to the manufacturer’s recommendations for the break-in duration to ensure smooth and silent strut operation.

-

Improper Installation or Torqueing

Incorrect installation or insufficient torquing of the strut assembly components can lead to noise issues. This can involve improperly fastened bolts, nuts, or mounting hardware, causing the strut to vibrate or create unwanted sounds during vehicle operation. Adequate torque and precision during installation are critical to prevent such disturbances.

-

Defective or Low-Quality Struts

The quality of the struts themselves plays a significant role. Inferior or defective strut components, such as poor-quality seals, insufficient lubrication, or subpar materials, can lead to premature wear or internal friction, resulting in unwarranted noise. Investing in high-quality struts from reputable manufacturers is crucial to avoid such issues.

-

Misalignment or Interference

Misalignment or interference issues within the suspension system can cause noise in new struts. This misalignment could be due to improper fitment, conflicts with other components, or inaccuracies in the assembly. Misalignment causes undue stress on the struts, leading to noise and potential damage. Ensuring proper alignment and clearances during installation is essential to prevent such disturbances.

-

Inadequate Lubrication

Insufficient or improper lubrication of the strut components, such as the strut bearings or seals, can result in increased friction and noise. Without adequate lubrication, the movement of the struts becomes less smooth, leading to audible disturbances. Regular maintenance, including appropriate lubrication, is necessary to ensure the proper functioning of the struts.

-

Worn or Damaged Mounts

Worn or damaged strut mounts, which are responsible for securing the struts to the vehicle’s chassis, can cause noise issues. Over time, these mounts can deteriorate, leading to a lack of support and increased movement of the struts. This increased movement may result in noises emanating from the mounting points. Regular inspection and replacement of worn mounts are crucial to prevent these noise disturbances.

How do I stop my struts from squeaking?

Addressing squeaking struts involves a series of steps aimed at ensuring proper installation, confirming quality, adhering to break-in periods, and seeking expert consultation. Here’s a comprehensive guide to prevent and resolve squeaking in struts:

-

Consultation with the Installer or Mechanic

If squeaking occurs after installing new struts, seeking guidance from the installer or a professional mechanic is the first step. Communicating the issue and the circumstances when the noise is most prevalent helps in identifying potential causes. The installer’s insights or a mechanic’s evaluation can reveal if the noise stems from installation issues, component quality, or other factors.

-

Confirming Proper Installation and Torque

Ensuring that the struts are installed correctly is crucial. Bolts, nuts, and mounting hardware need to be adequately torqued to manufacturer specifications. Loose or improperly fastened components can lead to vibrations and subsequent squeaking. Professional installers or mechanics verify the installation to prevent such issues.

-

Considering Break-In Period Recommendations

Adhering to the manufacturer’s recommended break-in period is essential for new struts. This break-in phase allows the components to settle and adapt to their working conditions. During this period, minor misalignments or initial friction issues can adjust, contributing to quieter strut operation. Not adhering to the break-in period might lead to premature noise issues.

-

Assessing the Quality of the Struts

The quality of the strut components significantly impacts their performance. Low-quality or defective struts, such as those with poor seals, inadequate lubrication, or inferior materials, can lead to premature wear and squeaking. Investing in high-quality struts from reputable manufacturers helps prevent potential noise problems.

Additional Steps to Address Squeaking Struts

- Lubrication: Ensure proper lubrication of components like strut bearings or seals to reduce friction and prevent squeaking. Regular maintenance, including appropriate lubrication, is crucial for smooth strut operation.

- Alignment and Clearances: Confirm proper alignment and clearances during installation to prevent misalignment issues that can cause stress on the struts, leading to noise disturbances.

- Inspect Mounts: Regularly inspect and replace worn or damaged strut mounts. Over time, these mounts may deteriorate, causing a lack of support and resulting in increased movement and noises at mounting points.

- Periodic Maintenance: Routinely inspect the struts for signs of wear, damage, or leaks. Timely maintenance ensures the longevity and efficient performance of the suspension system.

Addressing squeaking struts involves a multifaceted approach, starting with consultation and inspection by professionals to diagnose the cause. Proper installation, adherence to break-in periods, using quality components, and regular maintenance are vital in preventing and addressing squeaking issues. By taking these steps, you can ensure a quiet, well-functioning suspension system and a smoother, more comfortable driving experience.

Why are my new struts so bouncy?

New struts exhibiting excessive bounciness might prompt concern but can be attributed to several reasons, especially in the initial stages following installation.

-

Break-in Period

One primary reason for bouncy behavior in new struts is the lack of a proper break-in period. These components, upon installation, require a period to adjust and settle into their operational state. During this break-in phase, minor misalignments or initial friction issues can cause bounciness, which typically resolves as the struts adapt to their role in the suspension system.

-

Adjustment and Adaptation

Another cause can be the adjustment phase of the newly fitted struts. These components might behave differently initially due to variations in design or construction from the previous set. The new struts need time to adapt to the vehicle’s weight and driving conditions, which can result in a slightly bouncier ride until they fully settle and function optimally.

-

Quality and Compatibility

Additionally, bounciness could be related to the quality of the struts or potential compatibility issues. Lower-quality struts may not provide the necessary support or dampening capabilities, leading to increased bounce. Ensuring that the new struts are compatible with the vehicle’s specifications and of high quality is crucial to avoid such issues.

FAQs About New Struts Making Noise When Turning

Are new struts supposed to be stiff?

New struts might initially feel slightly stiff due to their construction and the need to settle. However, excessive stiffness or rigidity could indicate issues that might need adjustment or further evaluation.

How long does the break-in period for new struts typically last?

The break-in period for new struts often lasts around 100-500 miles. During this phase, the struts adjust and settle into their functional state within the vehicle.

Why do my new struts make noise when going over bumps?

Noise from new struts over bumps might stem from installation issues, misalignment, or potentially low-quality components. A professional assessment is advised to pinpoint the cause.

Can I replace just one strut or replace them in pairs?

It’s generally recommended to replace struts in pairs to ensure balanced suspension performance. However, individual replacement might suffice in certain cases, but consulting a mechanic for guidance is ideal.

How often should I replace my struts? What causes new struts to go bad?

Struts typically need replacement every 50,000 to 100,000 miles. Factors like poor road conditions, heavy use, or low-quality components can lead to premature wear and failure.

How do you lubricate struts?

Lubricating struts involves applying silicone-based lubricants or greases to specific points like mounts and pivot joints. Consultation with a professional is recommended for proper application.

What causes strut knock?

Strut knock might occur due to worn-out or damaged strut mounts, misalignment, or insufficient lubrication. These issues cause the struts to move or vibrate, resulting in knocking sounds.

Why is my new strut making noise when turning?

Noise from a new strut during turning might be due to misalignment, improper installation, or low-quality components. Professional inspection is necessary to diagnose and rectify the issue.

What is the best spray for squeaky suspension?

Silicone-based lubricants or specific suspension lubricants available in the market are commonly recommended to address squeaky suspensions.

Is it safe to drive with noisy struts?

Driving with noisy struts can be safe initially but might lead to potential issues if left unaddressed. Seeking professional advice and resolving the problem is advisable for safety and optimal performance.

Why does my suspension squeak when I turn?

Squeaking when turning often relates to issues such as worn-out components, lack of lubrication, or misalignment. Proper diagnosis and maintenance can resolve the squeaking.

Is squeaky suspension easy to fix?

Resolving squeaky suspension involves identifying the cause, which might range from lubrication to worn-out components. While some issues might be easy to fix, others may require professional attention for a thorough resolution.

Also Read: How To Fix Rattling In Steering Wheel: A Complete Guide

Conclusion

Understanding the functions, maintenance, and potential issues concerning struts within a vehicle’s suspension system is pivotal for a safe, comfortable driving experience. From the significance of proper installation, adherence to break-in periods, and ensuring high-quality components to the diagnosis and resolution of common strut-related concerns, this comprehensive overview provides essential insights for vehicle owners.

Struts, integral to a vehicle’s stability and handling, require meticulous attention. Recognizing signs of misalignment, noise, or bounciness in new struts necessitates a systematic approach—seeking professional guidance, ensuring compatibility, and adhering to recommended maintenance schedules.

The guidance of professional installers or mechanics remains paramount in diagnosing and rectifying issues effectively. Attention to detail during installation, monitoring the break-in period, and periodic maintenance are critical aspects of preserving a well-functioning suspension system.

This comprehensive understanding empowers drivers to take proactive measures to ensure the optimal performance and longevity of their vehicle’s struts. By adhering to recommended practices and seeking expert advice, vehicle owners can maintain a smoother, safer driving experience, ensuring their vehicle operates optimally for miles to come.