To ensure proper fuel pressure using OBD2, you’ll need an OBD2 scanner and access to your vehicle’s OBD2 port.

Connecting the scanner enables access to fuel pressure data within its menu, which should be interpreted against manufacturer specifications.

These readings aid in diagnosing fuel pressure irregularities, facilitating necessary steps for resolving any issues, and ensuring consistent upkeep for peak performance.

In the realm of vehicle functionality, maintaining adequate fuel pressure holds immense significance, be it in a gasoline or diesel engine.

It stands as a critical factor influencing performance and fuel efficiency. Thankfully, the integration of On-Board Diagnostic 2 (OBD2) systems in modern vehicles grants us the ability to monitor and identify potential issues, specifically related to fuel pressure complications.

This article aims to detail the process of assessing fuel pressure through OBD2 and underline its pivotal role in maintaining vehicles. By exploring this method, the significance of checking fuel pressure using OBD2 for consistent vehicle maintenance becomes apparent.

What is a Fuel Pressure?

Fuel pressure refers to the force generated within a vehicle’s fuel system to push fuel from the tank to the engine. It’s a critical measurement of the pressure at which the fuel is delivered to the engine’s injectors or carburetor. Maintaining the right pressure is essential for proper engine performance and fuel efficiency.

In both gasoline and diesel engines, fuel pressure ensures an adequate and consistent flow of fuel, which is vital for combustion. If the pressure is too high or too low, it can adversely affect the engine’s performance, leading to issues such as poor acceleration, inefficient fuel consumption, or even engine misfires.

Monitoring and maintaining the correct fuel pressure is crucial in ensuring the optimal functioning of a vehicle’s engine. This is often done through diagnostic tools like an OBD2 scanner, which allows for real-time monitoring and detection of potential fuel pressure problems.

Important: Driving With A Bad Oil Pressure Sensor: Any Real Risks?

How Does OBD2 Contribute to Fuel Pressure Diagnosis?

OBD2 (On-Board Diagnostics II) serves a pivotal role in diagnosing fuel pressure issues in modern vehicles. Its contribution to fuel pressure diagnosis is multifaceted and essential for maintaining optimal engine performance:

-

Monitoring and Access to Data

OBD2 systems provide access to various engine parameters, including fuel pressure readings. This real-time data monitoring allows mechanics and vehicle owners to assess the current fuel pressure levels, which is crucial for diagnosing issues.

-

Diagnostic Trouble Codes (DTCs)

When an issue with fuel pressure arises, OBD2 systems generate specific Diagnostic Trouble Codes related to the problem. These codes offer insights into the nature of the issue, aiding in pinpointing the exact cause of the fuel pressure anomaly.

-

Enhanced Precision in Diagnosis

OBD2 scanners offer advanced diagnostic capabilities. They not only provide access to fuel pressure data but also allow for a more precise and accurate diagnosis by analyzing the readings against manufacturer-specified parameters.

-

Efficient Problem Identification

Through OBD2’s ability to retrieve and display information on fuel pressure, potential problems can be identified swiftly. This enables early detection and resolution, preventing further damage to the engine caused by fluctuating or incorrect fuel pressure levels.

-

Regular Maintenance and Longevity

OBD2’s role in fuel pressure diagnosis promotes regular maintenance. By addressing fuel pressure issues promptly, it ensures the longevity and smooth functioning of the vehicle’s engine, contributing to overall reliability and performance.

What Are the Step-by-Step Procedures to Check Fuel Pressure Using OBD2?

Checking fuel pressure using OBD2 involves a systematic process that integrates technology and hands-on inspection. By following a step-by-step approach, you can effectively utilize OBD2 for monitoring and diagnosing fuel pressure issues in your vehicle.

Step1: Access to OBD2 Tools

To begin, gather essential tools: an OBD2 scanner and a vehicle with an OBD2 port. These scanners come in various forms, from basic code readers to more advanced diagnostic tools. Ensure compatibility between the scanner and your vehicle’s OBD2 system.

Step 2: Locating the OBD2 Port

Find the OBD2 port in your vehicle, usually located under the dashboard, either near the steering wheel or the driver’s side. Once located, plug the OBD2 scanner into this port.

Step 3: Connecting and Accessing Fuel Pressure Data

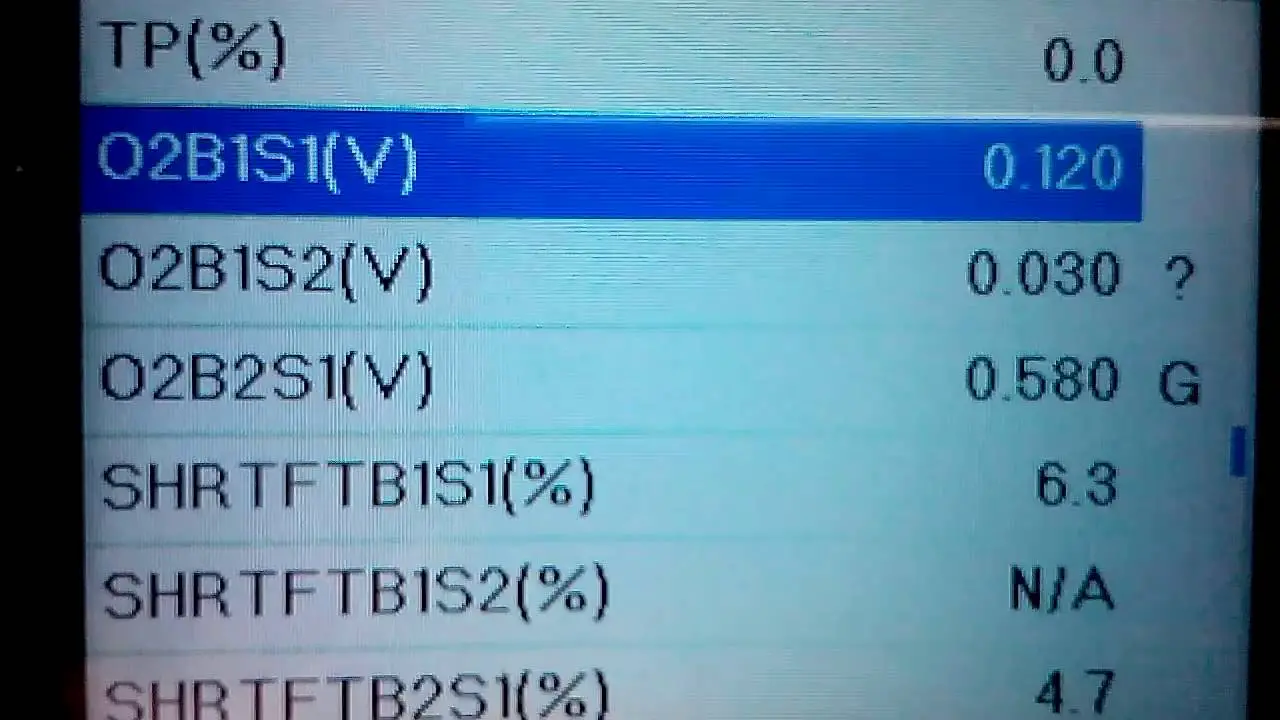

With the scanner connected, power on your vehicle. Access the scanner’s menu to select the option for reading fuel pressure data. Depending on the scanner, this information might be found under “Live Data” or “Data Stream.”

Step 4: Interpreting the Readings

The scanner will display the current fuel pressure readings. Compare these figures against the manufacturer’s specifications for your vehicle. Ensure the pressure levels align with the recommended range, which may vary based on your vehicle’s make and model.

Step 5: Diagnosis and Resolution

If the readings indicate irregular fuel pressure, this could signal an issue. This is where OBD2 becomes invaluable. It generates diagnostic trouble codes (DTCs), providing specific information about potential problems related to fuel pressure. Use these codes to identify and address the root cause of the discrepancy. Potential issues might involve a malfunctioning fuel pump, a clogged fuel filter, or a faulty pressure regulator.

Step 6: Maintenance and Resolution Steps

Once you’ve diagnosed the problem, take appropriate steps for resolution. This might involve replacing faulty components, cleaning clogged parts, or addressing any underlying issues causing the irregular fuel pressure.

Diagnosing Fuel Pressure Issues

Fuel pressure issues can significantly impact an engine’s performance, regardless of whether it’s low or high pressure. Diagnosing these problems is crucial for maintaining a vehicle’s efficiency and preventing potential damage to the engine. The process involves thorough inspection and, if necessary, calibration or repair to restore the optimal fuel pressure level.

Understanding Fuel Pressure Issues

Fuel pressure serves as the force that ensures the right amount of fuel reaches the engine for combustion. Low or high fuel pressure can cause various problems:

- Low Fuel Pressure

It can lead to poor engine performance, reduced power, hesitation during acceleration, and potential misfires. This issue often arises from problems with the fuel pump, fuel filter, or pressure regulator.

- High Fuel Pressure

It can cause excessive fuel consumption, engine knocking, and potential damage to the engine. This problem may stem from a malfunctioning fuel pressure regulator or a blocked fuel return line.

Addressing Low Fuel Pressure

Diagnosing Low Fuel Pressure

To identify low fuel pressure, an OBD2 scanner is a valuable tool. Connecting the scanner and accessing the live data section allows real-time monitoring. Compare the readings with manufacturer specifications to confirm if the pressure falls below the recommended range.

Additionally, listen for unusual sounds near the fuel tank, which could indicate a failing fuel pump. Inspecting the fuel filter for clogs or the pressure regulator for malfunctions is also advisable.

Steps to Resolve Low Fuel Pressure

Step 1: Check the Fuel Pump

If the fuel pump is failing, it might not generate enough pressure. Test its output pressure with a gauge and replace if necessary.

Step 2: Inspect the Fuel Filter

A clogged filter impedes fuel flow, causing low pressure. Replace the filter if it’s dirty or clogged.

Step 3: Examine the Pressure Regulator

Malfunctioning pressure regulators can lead to irregular pressure. Check for proper functioning or replace as needed.

Step 4: Address Leaks or Blockages

Leaks or blockages in the fuel lines can contribute to low pressure. Inspect and fix any issues in the lines.

Resolving High Fuel Pressure

Diagnosing High Fuel Pressure

High fuel pressure can be equally problematic. Again, an OBD2 scanner plays a key role in diagnosing this issue. The scanner will reveal readings that surpass the manufacturer’s recommended specifications, indicating elevated pressure levels.

Apart from the OBD2 data, symptoms like strong fuel odors or visible leaks in the fuel system might also suggest high-pressure issues.

Steps to Resolve High Fuel Pressure

Step 1: Check the Pressure Regulator

A faulty regulator might cause excessive pressure. Inspect it for proper functionality and replace if needed.

Step 2: Inspect the Fuel Return Line

A blocked return line can cause pressure buildup. Clear any blockages to restore normal flow.

Step 3: Check for Obstructions

Inspect the fuel lines for any obstructions that might cause pressure irregularities.

Step 4: Regulate the Pump Output

A malfunctioning fuel pump might generate too much pressure. Adjust or replace the pump as necessary.

Diagnosing and addressing fuel pressure issues, whether low or high, is crucial for maintaining a vehicle’s performance and longevity. Using diagnostic tools like OBD2 scanners, along with visual inspections, helps in identifying the problem.

Addressing low pressure involves resolving issues with the pump, filter, or pressure regulator. Resolving high pressure often revolves around regulating the pressure regulator, examining the return line, or checking for fuel line blockages.

Regular maintenance and prompt attention to fuel pressure irregularities are key in ensuring the smooth operation and longevity of a vehicle’s engine. When in doubt, consulting a professional mechanic for thorough inspection and resolution is advisable.

What are the Steps Involved in Checking Fuel Injectors Using an OBD2 Scanner?

Checking fuel injectors using an OBD2 scanner involves a methodical process that combines technology with on-the-ground analysis. An OBD2 scanner is a valuable tool that aids in diagnosing potential issues with fuel injectors, ensuring the proper functioning of a vehicle’s engine. Here’s a comprehensive guide on how to check fuel injectors using an OBD2 scanner:

Step 1: Preparation and Access to OBD2 Tools

- Acquire an OBD2 Scanner

First, ensure you have access to a compatible OBD2 scanner. These scanners are available in various types, ranging from basic code readers to more sophisticated diagnostic tools. Ensure the scanner is compatible with your vehicle’s OBD2 system.

- Locate the OBD2 Port

Identify and locate the OBD2 port in your vehicle, generally situated under the dashboard area. Once found, plug the OBD2 scanner into this port.

Step 2: Connecting the OBD2 Scanner

- Power On the Vehicle

Start the vehicle’s engine, allowing the OBD2 scanner to power on.

- Access Injector Data

Navigate through the OBD2 scanner’s menu to access injector data. Look for sections related to live data or data streams that include injector readings.

- Review Injector Data

The OBD2 scanner will display real-time data related to the fuel injectors. Monitor the readings for each injector, assessing their performance and ensuring consistency.

Step 3: Interpretation of Injector Readings

- Compare Readings

Compare the readings displayed by the OBD2 scanner against manufacturer specifications. The ideal values for injector performance can vary based on the vehicle’s make and model. Look for consistency and deviations from the standard.

- Check for Irregularities

Analyze the injector readings for irregularities. Variances or abnormally high or low readings compared to the standard values might indicate potential issues with specific injectors.

Step 4: Diagnosing Potential Injector Problems

- Interpret Diagnostic Trouble Codes (DTCs)

The OBD2 scanner might generate Diagnostic Trouble Codes (DTCs) if it detects issues with the injectors. These codes offer specific information on potential problems, aiding in pinpointing the root cause of any injector-related discrepancies.

- Inspect for Physical Symptoms

Physically examine the injectors for symptoms of malfunction such as leaks, blockages, or corrosion. Additionally, listen for irregular injector operations that may produce hissing or clicking sounds.

Step 5: Resolving Injector Issues

- Cleaning or Replacing Injectors

Address any detected issues by cleaning or replacing faulty injectors. If there are blockages or signs of damage, professional cleaning or replacement might be necessary.

- Addressing Fuel Delivery Problems

If injector issues persist, inspect other components related to fuel delivery, such as the fuel pump or fuel filter. Ensuring an adequate fuel supply is crucial for proper injector operation.

Also Read: Transmission Problems After Engine Swap: Troubleshooting Guide

FAQs About How to Check Fuel Pressure with OBD2

How do I check my fuel pump pressure without a gauge?

Without a gauge, you can assess fuel pump pressure through various indirect methods. Listen for a buzzing sound when the ignition is turned on, indicating the pump’s operation. Check for fuel leaks near the pump and test the engine’s performance during acceleration; sputtering or stalling might indicate pressure issues.

Additionally, pressing the valve stem on the fuel rail can provide a glimpse of the pump’s pressure—fuel should spurt out with force. However, these methods only offer approximate insights and are less precise compared to using a pressure gauge for an accurate measurement of fuel pump pressure.

Can a scanner detect a bad fuel pump?

An advanced OBD2 scanner can help detect issues related to a faulty fuel pump. By analyzing live data and diagnostic trouble codes (DTCs), the scanner can identify irregularities in fuel pressure, abnormal pump operation, or related sensor readings.

DTCs specifically associated with fuel delivery issues or low/high fuel pressure can indicate potential problems with the fuel pump. However, while a scanner can provide clues about the pump’s performance, a comprehensive diagnosis often requires additional physical inspection and testing to confirm and address the fuel pump’s malfunction.

What is the normal fuel pressure?

Normal fuel pressure varies among vehicles due to different engine designs and fuel systems. In general, fuel-injected systems typically maintain pressure within a range of 30 to 60 psi (pounds per square inch) while the engine is running. This range can differ for specific vehicle models and fuel types.

Consult the manufacturer’s specifications or the vehicle’s manual to determine the exact normal fuel pressure for your particular make and model. Understanding the recommended fuel pressure is essential for diagnosing and maintaining a vehicle’s optimal performance.

Where do you find fuel pressure?

Fuel pressure is found in the fuel system of a vehicle. Typically, it’s measured at the fuel rail, which is a pipe that supplies fuel to the engine’s fuel injectors. The fuel pressure gauge is attached to this rail to monitor the pressure within the system.

What are the symptoms of low fuel pressure?

Symptoms of low fuel pressure often include engine misfires, rough idling, reduced power during acceleration, difficulty starting the engine, hesitation or sputtering while driving, and potential stalling.

Additionally, there might be a noticeable drop in fuel efficiency, accompanied by a persistent strong smell of gasoline, indicating potential issues with the fuel system. Identifying and addressing these symptoms promptly is crucial, as low fuel pressure can adversely affect the engine’s performance and, if left unresolved, may lead to further complications.

Conclusion

In the realm of vehicle maintenance and diagnostics, understanding and monitoring fuel pressure is an integral aspect of ensuring optimal engine performance.

Utilizing tools like OBD2 scanners and gauges aids in identifying potential issues such as low or high fuel pressure, allowing for timely intervention.

Whether examining fuel injectors, the fuel pump, or overall system pressure, a systematic approach to diagnosing and resolving issues plays a crucial role in maintaining a vehicle’s efficiency. Regular checks, proper interpretation of readings, and prompt action when irregularities are detected are paramount.

Ultimately, a comprehensive understanding of fuel pressure and its diagnosis serves as a cornerstone in the ongoing care and longevity of a vehicle’s engine.