The high-pressure fuel pump is a crucial component in your vehicle’s engine that plays a vital role in ensuring its smooth operation. As the heart of the fuel delivery system, this pump is responsible for supplying pressurized fuel to the engine’s combustion chambers, ultimately powering your car or truck.

In this article, we will explore the significance of the high-pressure fuel pump and delve into various aspects related to its performance, maintenance, and potential issues. We’ll answer common questions such as the symptoms of pump failure, replacement costs, and how to maintain this critical component for your vehicle’s longevity and efficiency. So, let’s embark on this journey to understand the high-pressure fuel pump and keep your vehicle running at its best.

Also Read: Mastering Mass Air Flow Sensor: A Comprehensive Guide

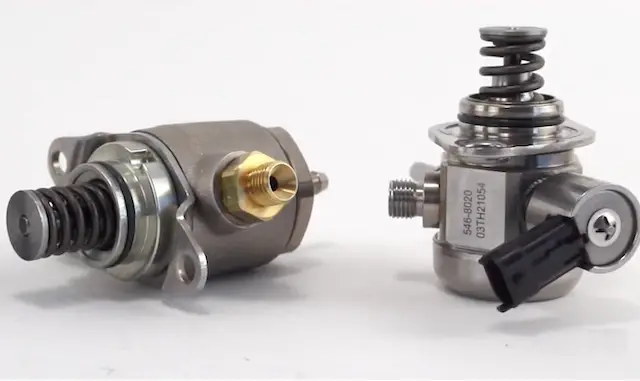

What is a high-pressure fuel pump?

The high-pressure fuel pump, commonly known as the HPFP, is a critical component of your vehicle’s engine. It is engineered to draw fuel from the fuel tank and deliver it to the engine at substantially higher pressure levels than the standard fuel pump. This pressurized fuel is vital for efficient combustion within the engine.

What is its role in the fuel delivery system?

The primary role of the high-pressure fuel pump is to elevate the pressure of the fuel it draws from the fuel tank. This pressurization is essential for modern fuel-injected engines, as it enables the precise delivery of fuel to the engine’s fuel injectors. These fuel injectors are responsible for spraying the fuel directly into the engine’s combustion chambers. This precise delivery of pressurized fuel is crucial to ensure the engine receives the right quantity of fuel at the correct pressure, which is fundamental for optimal engine performance.

Why is it essential for your vehicle’s performance and efficiency?

The high-pressure fuel pump is indispensable for enhancing your vehicle’s performance and fuel efficiency. Firstly, it contributes to improved combustion efficiency. By delivering fuel at high pressure, it facilitates the effective atomization of fuel particles, leading to more efficient and complete combustion. This results in increased power output and reduced emissions, both of which are essential for enhanced vehicle performance.

Secondly, the high-pressure fuel pump plays a crucial role in boosting fuel efficiency. The efficiency of the combustion process means that the engine extracts the maximum energy from the fuel it consumes, resulting in better fuel mileage and reduced fuel consumption.

Lastly, the high-pressure fuel pump ensures a responsive engine. This responsiveness is a key factor in delivering a smooth and enjoyable driving experience, as it enables the engine to promptly adapt to changes in throttle input. In summary, the high-pressure fuel pump is a cornerstone of your vehicle’s performance and fuel efficiency, ensuring the engine operates optimally, and providing the necessary power for a satisfying driving experience.

What are the common signs and symptoms of a failing high-pressure fuel pump?

When a high-pressure fuel pump begins to fail, it exhibits several noticeable symptoms, including:

- Loss of Power

One of the earliest signs is a noticeable decrease in engine power and overall vehicle performance. This can manifest as sluggish acceleration, reduced top speed, and poor throttle response.

- Engine Misfires

You may experience frequent engine misfires or hesitation when trying to accelerate. Misfires occur when the engine doesn’t receive the proper amount of fuel for combustion.

- Stalling

The engine may stall unexpectedly, particularly during idle or low-speed driving. This is often a result of irregular fuel delivery.

- Rough Idling

The engine may run unevenly or roughly when idling, causing noticeable vibrations and noise.

- Illuminated Check Engine Light

A failing high-pressure fuel pump can trigger the vehicle’s onboard diagnostics system, causing the check engine light to illuminate. Diagnostic trouble codes (DTCs) related to fuel pressure or injector performance are commonly associated with a failing pump.

- Poor Fuel Efficiency

Fuel efficiency typically declines as the engine struggles to maintain the correct air-fuel mixture. Reduced miles per gallon (MPG) is a common indicator of a problem.

How do these symptoms affect the vehicle’s performance?

The symptoms of a failing high-pressure fuel pump have a direct and negative impact on the overall performance of the vehicle:

- Reduced Power and Acceleration

The decrease in engine power and sluggish acceleration can make driving less enjoyable and potentially hazardous in situations where rapid acceleration is needed, such as merging onto highways or overtaking other vehicles.

- Engine Misfires and Hesitation

Engine misfires and hesitation not only compromise performance but can also damage the catalytic converter and other engine components over time, leading to expensive repairs.

- Stalling

Frequent stalling poses a significant safety concern, particularly when driving at high speeds or in heavy traffic, as it may result in a loss of control over the vehicle.

- Rough Idling

Rough idling not only affects driving comfort but also indicates an inefficient combustion process, potentially leading to damage to the engine over time.

- Check Engine Light

Ignoring the check engine light can lead to more severe issues and costly repairs if the underlying problem, such as a failing high-pressure fuel pump, is not addressed promptly.

- Poor Fuel Efficiency

Reduced fuel efficiency increases the cost of operating the vehicle and contributes to environmental pollution due to inefficient combustion.

What are the steps involved in testing a high-pressure fuel pump?

Testing a high-pressure fuel pump typically involves the following steps:

- Gather Essential Tools

Ensure you have the necessary tools and equipment for testing, including a fuel pressure gauge, safety glasses, a fire extinguisher, and a repair manual specific to your vehicle.

- Locate the Schrader Valve

Find the Schrader valve on the fuel rail. This is where you can attach the fuel pressure gauge.

- Relieve Fuel Pressure

Before testing, relieve the fuel pressure from the system to prevent fuel spray. This can usually be done by depressurizing the system through the Schrader valve.

- Attach the Pressure Gauge

Connect the fuel pressure gauge to the Schrader valve. This gauge will measure the pressure of the fuel system.

- Turn the Ignition Key

Turn the ignition key to the “On” position (without starting the engine). This will pressurize the fuel system, and the gauge should register the pressure.

- Read the Pressure

The gauge will display the current fuel pressure. Compare this reading to the manufacturer’s specifications for your vehicle. If it falls outside the specified range, it indicates a potential issue with the high-pressure fuel pump.

- Run Engine Tests

To further assess the pump’s performance, start the engine. Observe the fuel pressure on the gauge while the engine is idling, revving, and underload. Any significant fluctuations or drops may indicate pump problems.

- Monitor Fuel Pressure Stability

Fuel pressure should remain stable within the specified range during all engine operations. If the pressure fluctuates excessively or drops below the minimum threshold, the high-pressure fuel pump may be failing.

What tools and equipment are required for testing?

To test a high-pressure fuel pump, you will need the following tools and equipment:

- Fuel Pressure Gauge

This instrument measures the pressure of the fuel system.

- Safety Glasses

Protect your eyes from any potential fuel spray or accidents.

- Fire Extinguisher

It’s a safety precaution in case of any fuel-related mishap.

- Repair Manual

Having a repair manual specific to your vehicle is essential for understanding the testing procedure and the manufacturer’s specified fuel pressure range.

Can you perform the tests at home, or is professional help necessary?

Testing the high-pressure fuel pump can be performed at home if you have the necessary tools and are comfortable following the steps outlined in the repair manual. However, if you are unfamiliar with vehicle maintenance, it may be safer and more accurate to seek professional help. Automotive technicians have the expertise and experience to conduct thorough tests, diagnose any issues accurately, and perform the necessary repairs or replacements.

Additionally, some high-pressure fuel pump tests require specialized equipment that may not be readily available to the average vehicle owner. If in doubt, it’s recommended to consult a professional to ensure a proper diagnosis and resolution of any high-pressure fuel pump issues.

What factors influence the cost of replacing a high-pressure fuel pump?

The cost of replacing a high-pressure fuel pump can vary based on several factors, including:

- Vehicle Make and Model

Different vehicles have varying levels of complexity in their fuel systems. Some may require more extensive disassembly for pump access, impacting labor costs.

- Pump Type

High-pressure fuel pumps come in various types, such as mechanical or electronic. Electronic pumps can be more expensive due to their sophisticated design.

- Labor Costs

Labor rates vary by location and repair shop. More extensive and complex installations may require more time, leading to higher labor charges.

- OEM or Aftermarket Parts

Choosing original equipment manufacturer (OEM) parts tends to be more expensive than using aftermarket alternatives, but OEM parts often come with higher quality assurance.

- Warranty

Some replacement parts come with warranties that add to the overall cost. Higher-quality, more expensive parts may offer longer warranties.

What is the average price range for this replacement?

On average, the cost of replacing a high-pressure fuel pump can range from $500 to $1,000 or more. However, the actual cost can fall above or below this range based on the factors mentioned earlier. For example, luxury or high-performance vehicles might have higher replacement costs due to their specialized components and the need for more skilled labor.

It’s important to note that this cost is an estimate for parts and labor, and does not account for any additional repairs or diagnostic tests that may be required to ensure the high-pressure fuel pump replacement resolves the issue completely.

Are there any cost-saving tips or alternatives?

- Shop Around

Obtain quotes from multiple repair shops or mechanics to find the best price for the replacement.

- Consider Aftermarket Parts

Depending on your vehicle and circumstances, aftermarket high-pressure fuel pumps can be a cost-effective alternative to OEM parts. However, be sure to choose reputable brands for reliability.

- Regular Maintenance

Maintaining your vehicle according to the manufacturer’s recommendations can help prevent fuel pump issues. Prevention is often more cost-effective than replacement.

- Warranty Consideration

If your vehicle is still under warranty, check if the high-pressure fuel pump replacement is covered. In some cases, the manufacturer may cover this cost.

- DIY Installation

If you’re experienced with vehicle repairs, you may consider replacing the high-pressure fuel pump yourself. However, this option is only recommended for those with the necessary skills and knowledge.

- Fuel System Cleaner

Regularly using a fuel system cleaner can help prevent fuel system issues and extend the life of your high-pressure fuel pump.

Relevant recalls or issues related to GM vehicles

In recent years, General Motors (GM) has experienced high-pressure fuel pump issues across several of its vehicle models. These problems have led to recalls and safety concerns. GM vehicle owners have reported symptoms such as engine misfires, stalling, and power loss, all of which have been linked to high-pressure fuel pump failures. Such issues have been prevalent in a range of GM vehicles, including trucks, SUVs, and certain car models.

How does the recall affect affected vehicle owners?

If you own a GM vehicle subject to a high-pressure fuel pump recall, the impact can vary. Recalls are initiated to address safety concerns, so it’s crucial to understand the potential risks associated with a failing high-pressure fuel pump. Some common effects of such recalls include:

- Safety

Recalls are intended to prevent safety issues associated with a defective component. Vehicle owners should be aware that continuing to drive a vehicle with a faulty high-pressure fuel pump can result in a range of problems, including potential engine failure and safety hazards.

- Free Repairs

GM typically covers the cost of replacing the high-pressure fuel pump and any other affected components as part of the recall. This means vehicle owners can have the necessary repairs done at no additional cost.

- Vehicle Downtime

While repairs are performed, affected vehicle owners may experience some inconvenience due to downtime, but it is a necessary step to ensure the vehicle’s safety and functionality.

What steps should GM vehicle owners take if their high-pressure fuel pump is recalled?

If your GM vehicle is subject to a high-pressure fuel pump recall, consider taking the following steps:

- Check for Recall Notifications

GM will typically send recall notifications to affected vehicle owners. Keep an eye on your mailbox and email for any notifications regarding the recall.

- Contact Your Dealership

Reach out to your local GM dealership to schedule an appointment for the recall repair. They will provide you with more information on the specific steps and timeframe for the replacement.

- Stay Informed

Stay informed about the progress of the recall and make sure to have the necessary repairs done promptly. Ignoring the recall can result in safety risks and potential damage to your vehicle.

- Documentation

Keep all records and paperwork related to the recall, including repair invoices, as they may be needed in the future.

What Happens if a High-Pressure Fuel Pump Fails

When a high-pressure fuel pump fails, it can have a range of consequences that impact the vehicle’s performance and overall operation. Some of these consequences include:

- Power Loss

One of the most immediate and noticeable effects is a significant reduction in engine power. The engine may struggle to accelerate, making the vehicle feel sluggish and unresponsive.

- Engine Misfires

High-pressure fuel pump failure can lead to inconsistent fuel delivery, causing engine misfires. This results in a rough-running engine and can lead to long-term engine damage.

- Stalling

A failing pump may not provide consistent fuel pressure, leading to engine stalling, particularly at idle or low speeds. Stalling can be dangerous, especially in traffic or at intersections.

- Poor Fuel Efficiency

The inefficient delivery of fuel can lead to poor fuel economy, as the engine struggles to maintain the correct air-fuel mixture.

How does it impact the engine, vehicle performance, and safety?

The impact of a high-pressure fuel pump failure extends to several critical areas:

- Engine Performance

Engine performance suffers due to reduced power, misfires, and poor fuel efficiency. The engine may run roughly, and its responsiveness can be compromised.

- Safety Concerns

High-pressure fuel pump failures can lead to unsafe conditions, including engine stalling, which can be especially hazardous in high-speed situations or when merging onto highways. Sudden power loss and misfires can affect the driver’s ability to control the vehicle safely.

- Long-Term Engine Damage

Extended operation with a failing high-pressure fuel pump can result in further damage to the engine. Engine misfires, inefficient combustion, and lean-running conditions can lead to damaged valves, pistons, and catalytic converters, resulting in expensive repairs.

- Emissions and Environmental Impact

Inefficient combustion caused by high-pressure fuel pump failure can result in increased emissions, contributing to environmental pollution.

What are the differences between a weak fuel pump and a failing high-pressure fuel pump?

It’s important to distinguish between a weak fuel pump and a failing high-pressure fuel pump because the symptoms and implications are different:

- Weak Fuel Pump

A weak fuel pump typically means that the pump is unable to maintain adequate fuel pressure. This may result in issues like poor acceleration, engine hesitation, and reduced power. It may still function adequately at idle or low loads, but it struggles to provide sufficient fuel under high demand.

- Failing High-Pressure Fuel Pump

A failing high-pressure fuel pump, on the other hand, usually leads to more severe symptoms such as engine misfires, stalling, rough idling, and significant power loss. It is often characterized by an inability to maintain consistent fuel pressure at all times.

What signs indicate a weak fuel pump, and how is it diagnosed?

Identifying a weak fuel pump involves recognizing specific signs and conducting diagnostic tests:

Common Signs of a Weak Fuel Pump

- Poor Acceleration

A weak fuel pump may struggle to provide the necessary fuel under heavy acceleration, leading to a lack of power and slow acceleration.

- Hesitation

The engine may hesitate or stumble when you press the throttle. This hesitation is particularly noticeable during rapid acceleration or when overtaking other vehicles.

- Engine Stalling

In some cases, a weak fuel pump can lead to engine stalling, especially at low speeds or when idling. This is often due to inadequate fuel supply.

- Reduced Fuel Efficiency

A weak fuel pump can cause poor fuel efficiency as the engine struggles to maintain the correct air-fuel mixture, resulting in lower miles per gallon (MPG).

Diagnosis of a Weak Fuel Pump

- Fuel Pressure Test

To diagnose a weak fuel pump, a fuel pressure test is conducted. This test involves attaching a fuel pressure gauge to the fuel system and measuring the pressure while the engine is running. If the pressure falls below the manufacturer’s specified range, it indicates a weak fuel pump.

- Flow Test

In addition to pressure, a flow test can be performed to determine if the fuel pump can supply an adequate amount of fuel to the engine under various conditions. A weak fuel pump may pass a static pressure test but fail a flow test under load.

- Fuel Volume Test

This test measures the volume of fuel the pump can deliver over time. It helps determine if the pump can maintain a consistent fuel supply, which is essential for engine performance.

Factors and conditions that can lead to high-pressure fuel pump damage

High-pressure fuel pumps, like any mechanical component, can be vulnerable to damage due to various factors and conditions:

- Contaminated Fuel

Fuel with contaminants such as dirt, rust, or water can damage the high-pressure fuel pump. These particles can wear down the pump’s components, leading to reduced performance and potential failure.

- Lack of Lubrication

A high-pressure fuel pump relies on fuel for lubrication. When fuel quality is poor or insufficient, it can result in increased friction and wear on the pump’s internal components.

- Excessive Heat

High-pressure fuel pumps operate in a high-temperature environment. Prolonged exposure to excessive heat can lead to component fatigue and reduced pump efficiency.

- Excessive Pressure

While the pump is designed to provide high pressure, exceeding its designed limits can cause damage. This can occur if the vehicle’s fuel system is modified to increase pressure beyond the pump’s capacity.

- Clogged Fuel Filters

Fuel filters help remove contaminants from the fuel before it reaches the high-pressure pump. Neglecting to replace clogged filters can lead to increased strain on the pump and potential damage.

- Running on Empty

Operating a vehicle with very low fuel levels can cause the pump to draw air instead of fuel, leading to overheating and damage.

- Poor Fuel Quality

Using low-quality or contaminated fuel over an extended period can cause damage to the pump’s components and reduce its lifespan.

Tips on how to prevent damage and prolong the pump’s lifespan

To extend the lifespan of your high-pressure fuel pump and prevent damage, consider the following tips:

- Use High-Quality Fuel

Always use high-quality, clean fuel from reputable sources. This helps ensure that the fuel entering the pump is free from contaminants that could cause damage.

- Change Fuel Filters Regularly

Replace fuel filters at the recommended intervals to prevent clogs that can strain the pump.

- Keep the Tank Half Full

Avoid running your vehicle on low fuel levels. Keeping the tank at least half full can help prevent the pump from drawing in air.

- Regular Maintenance

Follow the manufacturer’s recommended maintenance schedule for your vehicle. This includes checking and maintaining the fuel system.

- Coolant System Maintenance

Ensure that your vehicle’s cooling system is in good condition, as excessive heat can affect the pump’s performance.

- Avoid Modifications

Avoid making unauthorized modifications to the fuel system, as these can lead to excessive pressure and pump damage.

- Monitor Fuel Quality

Be aware of the fuel quality in your area, and if possible, choose reputable fueling stations that provide clean, high-quality fuel.

- Use Fuel Additives

Some fuel additives can help clean and lubricate the fuel system, potentially extending the pump’s lifespan.

Can I Drive with a Faulty High-Pressure Fuel Pump?

Driving with a faulty high-pressure fuel pump can have significant safety and mechanical implications, as it directly affects the vehicle’s performance and reliability:

- Safety Concerns

A failing high-pressure fuel pump can lead to sudden power loss, engine misfires, and stalling. These issues can compromise your ability to control the vehicle safely, especially during critical moments like merging onto highways or overtaking other vehicles.

- Engine Damage

Continued operation with a faulty high-pressure fuel pump can damage other engine components. Engine misfires and lean-running conditions can lead to damage to the valves, pistons, and catalytic converter. This results in costly repairs and potential engine failure.

- Reduced Fuel Efficiency

A faulty pump can result in poor fuel efficiency, causing increased fuel consumption. This not only costs more in terms of fuel but also contributes to environmental pollution.

- Emissions

Inefficient combustion due to a failing high-pressure fuel pump can increase emissions, making the vehicle environmentally unfriendly and potentially leading to legal issues in areas with strict emissions regulations.

Guidance on when it’s safe to drive and when it’s not

The safety of driving with a faulty high-pressure fuel pump depends on the severity of the issue and the specific symptoms:

- Safe to Drive

If the symptoms of a failing high-pressure fuel pump are mild, such as occasional hesitation or rough idling, you may be able to drive short distances at lower speeds. However, it’s crucial to prioritize safety and seek repairs as soon as possible.

- Unsafe to Drive

If the symptoms are more severe, such as engine stalling, significant power loss, or continuous misfires, it’s unsafe to drive the vehicle. Continuing to operate a vehicle in this condition can pose a considerable risk to your safety and the safety of others on the road.

- Temporary Use Only

In cases of mild symptoms, you should consider driving to a repair facility only if it’s within a short distance and at low speeds. However, the goal should always be to address the issue promptly to prevent further damage or safety risks.

How Often Should You Replace a High-Pressure Fuel Pump?

High-pressure fuel pumps are critical components in a vehicle’s fuel delivery system, and their typical lifespan can vary depending on several factors.

Typical Lifespan

The lifespan of a high-pressure fuel pump can vary, but it is generally expected to last anywhere from 100,000 to 150,000 miles or more in a well-maintained vehicle. However, some high-quality pumps may last significantly longer.

Factors Influencing Replacement Interval

Several factors can influence when a high-pressure fuel pump should be replaced:

- Maintenance

Proper maintenance is a significant factor in determining the lifespan of the high-pressure fuel pump. Regular fuel system maintenance, including changing fuel filters and using high-quality fuel, can extend the pump’s life.

- Fuel Quality

The quality of fuel used in the vehicle can significantly impact the pump’s lifespan. Using clean, high-quality fuel free of contaminants and water helps prevent premature wear and damage.

- Driving Conditions

Aggressive driving, heavy loads, and frequent stop-and-go driving can put more stress on the high-pressure fuel pump, potentially leading to earlier replacement.

- Environmental Conditions

Extreme temperatures, especially excessive heat, can affect the pump’s longevity. Hotter climates may lead to shorter pump life.

- Manufacturer and Quality

The quality of the original equipment manufacturer (OEM) or aftermarket high-pressure fuel pump can vary. High-quality, reputable brands may offer longer-lasting pumps.

- Vehicle Make and Model

Some vehicle models may have designs that make high-pressure fuel pump replacement more labor-intensive and costly, influencing the decision on when to replace it.

- Driving Habits

Consistently running the vehicle with low fuel levels or running out of fuel can strain the high-pressure fuel pump and potentially lead to premature wear.

- Modifications

Any unauthorized modifications to the fuel system can affect the pump’s lifespan, especially if these modifications result in excessive pressure or other unfavorable conditions.

What are the significance of removing air from the fuel system?

Removing air from the fuel system is essential for maintaining the proper operation and efficiency of high-pressure fuel pumps. Air bubbles in the fuel system can disrupt the delivery of fuel to the engine, leading to various issues:

- Inefficient Combustion

Air in the fuel system can cause an improper air-fuel mixture, resulting in incomplete combustion. This leads to reduced engine power and poor fuel efficiency.

- Engine Misfires

Air bubbles can disrupt the fuel flow, causing engine misfires, rough idling, and poor acceleration.

- Reduced Fuel Pressure

Air can compress, causing fluctuations in fuel pressure. This inconsistency can affect the overall performance of the high-pressure fuel pump and engine.

- Stalling and Power Loss

Excessive air in the fuel system can cause engine stalling, especially during low-speed or idle conditions. It can also lead to a loss of power and poor throttle response.

Step-by-step instructions on how to bleed air from a high-pressure fuel pump

Bleeding air from a high-pressure fuel pump involves purging the air bubbles from the fuel system to restore proper fuel flow. Here are step-by-step instructions:

Note: Bleeding air from the fuel system may vary depending on the specific vehicle make and model. Always refer to your vehicle’s repair manual for the most accurate instructions.

- Safety Precautions: Before starting, ensure that the engine is off, the vehicle is in a safe and well-ventilated area, and all safety precautions are followed.

- Locate the Fuel Lines: Identify the fuel lines and the high-pressure fuel pump. The fuel lines may have bleed screws or fittings that need to be accessed.

- Depressurize the System: Release any residual pressure in the fuel system. This is typically done by disconnecting the fuel pump relay and cranking the engine a few times. This ensures safety during the bleeding process.

- Open the Bleed Screw: If your vehicle’s fuel system has a bleed screw or fitting, use the appropriate wrench to open it. Start with the fitting closest to the fuel tank and work your way toward the high-pressure fuel pump.

- Turn the Ignition Key: Turn the ignition key to the “On” position without starting the engine. This will activate the fuel pump and begin to push out the air from the system. Keep the bleed screw open while doing this.

- Monitor Fuel Flow: As you turn on the ignition, you should observe fuel flowing from the bleed screw without air bubbles. Once you see a continuous stream of fuel, close the bleed screw tightly.

- Crank the Engine: Start the engine and let it run for a few minutes. This will help ensure that any remaining air is purged from the system.

- Check for Leaks: After bleeding the system, check for fuel leaks around the connections. If there are no leaks, you’ve successfully removed air from the high-pressure fuel pump and the fuel system.

- Replace the Fuel Pump Relay: Once you’ve confirmed that the system is free of air and there are no leaks, you can reconnect the fuel pump relay.

Conclusion

The high-pressure fuel pump plays a vital role in your vehicle’s fuel delivery system, ensuring the efficient and consistent supply of fuel to the engine. Understanding its function and recognizing the symptoms of failure is essential for maintaining the performance, safety, and reliability of your vehicle.

Symptoms of high-pressure fuel pump failure, such as power loss, engine misfires, and stalling, should not be ignored. Prompt diagnosis and, if necessary, replacement are crucial to prevent further damage to the engine and ensure safe driving conditions.

Regular maintenance, including fuel filter changes, use of high-quality fuel, and adherence to the manufacturer’s maintenance schedule, can help prolong the lifespan of the high-pressure fuel pump and prevent potential issues. Additionally, being aware of recalls and addressing them promptly, as seen in GM’s recall case, is vital for safety and peace of mind.

While driving with a failing high-pressure fuel pump is generally discouraged due to safety and mechanical concerns, recognizing the severity of symptoms is key to determining when it is safe to drive and when it is not.

Bleeding air from the fuel system is another critical aspect of high-pressure fuel pump maintenance. Properly purging air bubbles ensures that the engine receives a consistent supply of fuel, preventing issues like engine misfires and poor fuel efficiency.