A crankshaft pulley might seem like a small, inconspicuous component in your car’s engine, but it plays a crucial role in the smooth operation of your vehicle. This article will explore the world of crankshaft pulleys, their functions, the signs of trouble to watch out for, and how to maintain or replace them when necessary.

What does a crankshaft pulley do?

The crankshaft pulley, often called a harmonic balancer, is essential to your car’s engine. Its primary function is to transmit power from the engine’s crankshaft to various accessories, such as the alternator, power steering pump, and air conditioning compressor. This enables these accessories to operate smoothly, providing essential features like electrical power and responsive steering.

Also Read: Serpentine Belt Tensioner & Tools: Your Comprehensive Guide

Importance of a crankshaft pulley in your car

While it may go unnoticed in your car’s engine bay, the crankshaft pulley plays a pivotal role in maintaining the overall functionality of your vehicle. A properly functioning pulley ensures that your car’s auxiliary systems operate efficiently. However, when it goes bad, it can lead to a cascade of issues affecting your car’s performance and safety.

In the following sections, we will explore the signs that indicate a faulty crankshaft pulley, the consequences of neglecting this crucial component, and how to keep it in good working condition. So, let’s dive into crankshaft pulleys and discover why they are essential for your car’s health and performance.

Signs of a Bad Crankshaft Pulley

How can you tell if you have a bad crankshaft pulley?

Your car’s crankshaft pulley may be small, but it greatly impacts your vehicle’s performance. To ensure your car is running smoothly, it’s essential to recognize the signs of a bad crankshaft pulley. Here’s how you can tell if yours is in trouble:

- Strange Noises

One of the most common indicators is unusual noises coming from the engine area. Listen for squealing, rattling, or grinding sounds when you start your car or while it’s running. These noises can be a result of a damaged or misaligned pulley.

- Vibrations

A failing crankshaft pulley can cause your car to vibrate more than usual, especially when idling or at low speeds. If you notice excessive vibrations, it’s time to inspect the pulley.

- Accessory Malfunctions

The crankshaft pulley drives accessories like the alternator, power steering pump, and air conditioning compressor. If any of these systems start to malfunction, it could be due to a failing pulley.

Bad crankshaft pulley symptoms

When your crankshaft pulley starts to go bad, it can manifest in various symptoms that affect your car’s performance and safety:

- Power Loss

A failing pulley may lead to a decrease in engine power. Your car might feel sluggish and unresponsive when you accelerate.

- Battery Trouble

If the crankshaft pulley drives the alternator and it fails, your battery may not charge properly. This can result in repeated battery drain and starting issues.

- Steering Problems

Power steering relies on the crankshaft pulley to function correctly. A problematic pulley can make steering more difficult, especially at low speeds.

- Overheating

The pulley also powers the water pump, which helps cool the engine. If the pulley fails, it can lead to engine overheating, potentially causing severe damage.

Crankshaft pulley wobble

A noticeable wobble in the crankshaft pulley is a clear sign of trouble. This wobbling can result from a damaged pulley, loose bolts, or misalignment. It’s crucial to address this issue promptly because an imbalanced pulley can further damage your engine and other components.

When you spot any of these signs or symptoms, having your crankshaft pulley inspected and repaired by a qualified mechanic is essential. Ignoring these warning signs could lead to more significant and costly problems.

Can the crankshaft pulley cause vibration?

The condition of your car’s crankshaft pulley can significantly impact your driving experience, and one noticeable effect is vibration. Here’s a closer look at how a faulty crankshaft pulley can cause vibration:

- Misalignment

When a crankshaft pulley becomes misaligned due to wear or damage, it can imbalance the engine’s rotating components. This imbalance leads to vibrations you’ll feel through the steering wheel, pedals, or even the entire vehicle. These vibrations can vary in intensity, becoming more pronounced at certain speeds or engine RPMs.

- Accessory Malfunctions

As mentioned, the crankshaft pulley drives essential accessories like the alternator and power steering pump. If the pulley isn’t functioning correctly, these accessories may operate sporadically or not at all, causing irregularities in your car’s performance and potentially contributing to vibrations.

Maintenance and Repair

Proper maintenance and timely repair of your car’s crankshaft pulley are crucial to ensure its smooth operation and prevent more significant issues. This section will explore various aspects of maintaining and repairing your crankshaft pulley.

Crankshaft Pulley Removal

Using a Crankshaft Pulley Removal Tool

Removing a crankshaft pulley can be challenging, but replacing a damaged pulley or performing other engine maintenance is essential. A crankshaft pulley removal tool is a specialized tool designed to make this job more manageable. Here’s a step-by-step guide on how to use it:

- Step 1: Safety First

Before you begin, ensure your car is parked on a level surface, the engine is off, and the battery is disconnected to prevent any accidental starts. Also, wear appropriate safety gear, including gloves and eye protection.

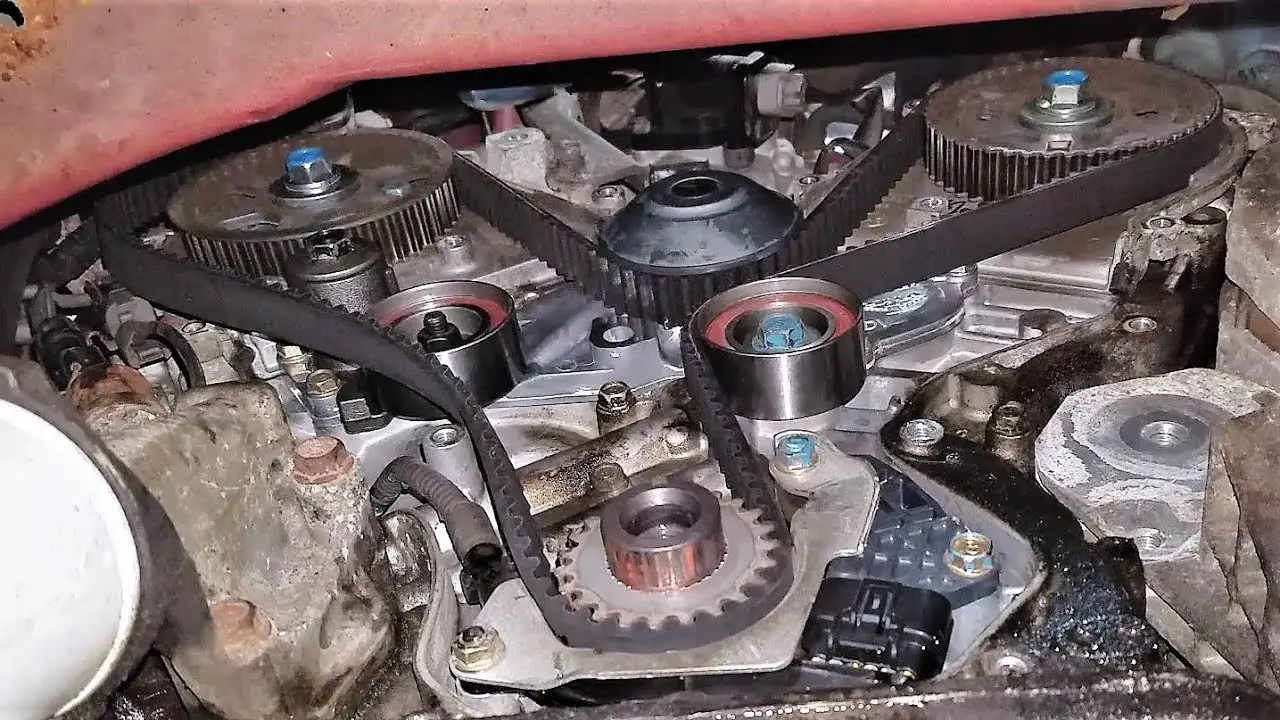

- Step 2: Locate the Crankshaft Pulley

The crankshaft pulley is typically located at the front of the engine, connected to the crankshaft. You may need to remove the serpentine belt that drives the pulley first.

- Step 3: Position the Removal Tool

Place the crankshaft pulley removal tool over the pulley. The tool should fit securely and align with the pulley’s bolt holes.

- Step 4: Secure the Tool

Use the provided bolts or fasteners to secure the removal tool to the pulley. Ensure it’s tightly attached, as this tool will exert significant force during removal.

- Step 5: Apply Force

Use a breaker bar or ratchet wrench to turn the removal tool counterclockwise. This will exert force on the pulley, loosening it from the crankshaft.

- Step 6: Remove the Pulley

As you turn the removal tool, you’ll notice the pulley starting to come off the crankshaft. Continue turning until the pulley is completely free.

- Step 7: Inspect the Pulley and Components

With the pulley removed, inspect it for any signs of wear, damage, or misalignment. This is also an excellent opportunity to check the condition of the crankshaft and related components.

How to Remove a Crankshaft Pulley Bolt Without an Impact Gun

If you don’t have access to an impact gun, you can still remove the crankshaft pulley bolt with some effort and the right tools. Here’s a manual method to accomplish this task:

- Step 1: Safety Precautions

As always, ensure your car is parked on a level surface, the engine is off, and the battery is disconnected. Wear safety gear, including gloves and eye protection.

- Step 2: Secure the Crankshaft

To prevent the crankshaft from turning while you loosen the bolt, place a large wrench or socket on the harmonic balancer (the big pulley connected) and use a breaker bar to hold it in place.

- Step 3: Loosen the Bolt

Use a socket wrench with an appropriately sized socket to fit the crankshaft pulley bolt. Turn the wrench counterclockwise to loosen the bolt. This may require considerable force, so ensure the breaker bar holding the crankshaft in place remains secure.

- Step 4: Remove the Bolt

Once the bolt is sufficiently loosened, you can remove it by hand. Be cautious not to let the crankshaft turn abruptly as you do this.

Related Post: Fuel Tank Pressure Sensor: Symptoms, Location, & Replacement

Crankshaft Pulley Replacement

If you’ve removed the crankshaft pulley and found it to be damaged or worn, replacing it is the best course of action. Here’s how you can replace the pulley:

- Step 1: Procure a Replacement Pulley

Ensure you have the correct replacement crankshaft pulley for your car’s make and model. You can typically find this part at an auto parts store or through your vehicle’s manufacturer.

- Step 2: Prepare the Area

Ensure the area where the pulley will be installed is clean and debris-free. Inspect the crankshaft and surrounding components for any damage or wear.

- Step 3: Install the New Pulley

Slide the new crankshaft pulley onto the crankshaft, ensuring it aligns correctly with the keyway or grooves. Push it on as far as it will go by hand.

- Step 4: Tighten the Pulley Bolt

Reattach the crankshaft pulley bolt and tighten it securely using a torque wrench. Refer to your vehicle’s service manual for the recommended torque specification, as overtightening or under-tightening can cause problems.

- Step 5: Reattach Accessories

If you had to remove any accessories like the serpentine belt, reattach them according to your car’s manual.

- Step 6: Reconnect the Battery

Reconnect the car’s battery and start the engine to ensure the pulley functions correctly. Listen for any unusual noises or vibrations.

Preventing Crankshaft Pulley Issues

- How to Stop a Crankshaft Pulley from Turning

When removing or installing a crankshaft pulley, it’s crucial to prevent it from turning, as the bolt holding it can be quite tight. Here’s a method to stop the pulley from turning:

- Step 1: Locate the Flywheel or Flexplate

Underneath your car is a flywheel or flexplate attached to the engine’s crankshaft. Locate the access point to this component, typically near the transmission bell housing.

- Step 2: Use a Flywheel Holder Tool

Insert a flywheel holder tool or a large, sturdy screwdriver into the access point to engage with the teeth of the flywheel or flexplate. This will prevent the crankshaft from turning as you work on the pulley bolt.

- Step 3: Loosen or Tighten the Pulley Bolt

With the flywheel holder tool, you can confidently loosen or tighten the crankshaft pulley bolt without worrying about the pulley turning.

This method ensures that you have the necessary stability to work on the crankshaft pulley without risking damage to the engine.

Crankshaft Pulley Installer

When replacing a crankshaft pulley, having the right tools for the job is essential. A crankshaft pulley installer tool can help you properly seat the new pulley onto the crankshaft, ensuring a secure and aligned fit. Follow the manufacturer’s instructions that come with the tool to ensure a successful installation.

Crankshaft Pulley Noise

If you’re experiencing unusual noises from your crankshaft pulley, addressing the issue promptly is crucial. Noises such as squealing, rattling, or grinding can be indicative of a problem with the pulley or related components. Ignoring these noises can lead to further damage and more expensive repairs. If you’re uncertain about the source of the noise or how to fix it, it’s advisable to consult a qualified mechanic to diagnose and resolve the issue.

Proper maintenance, repair, and attention to your car’s crankshaft pulley are essential for your vehicle’s overall health and performance. Whether you’re removing, replacing, or preventing issues with the pulley, following these guidelines can help ensure the smooth operation of your car’s engine and accessories. Remember that safety precautions and using the correct tools are crucial when working on your vehicle’s components.

Comparison with Harmonic Balancer

Crankshaft Pulley vs. Harmonic Balancer

Let’s look closer at the crankshaft pulley and the harmonic balancer – two important parts of your car that might seem similar but serve different purposes.

- Crankshaft Pulley

The crankshaft pulley ensures that various parts of your car work as they should. Its primary job is to turn things like the alternator, power steering, and air conditioning components. It connects to the engine’s crankshaft and helps spin these accessories, making them function properly.

- Harmonic Balancer

On the other hand, the harmonic balancer, although connected to the crankshaft, has a different job. It acts like a helper or stabilizer for your engine. When your engine runs, it produces vibrations and shakes. The harmonic balancer absorbs some of these vibrations, keeping your engine running more smoothly.

Harmonic Balancer vs. Crankshaft Pulley

Now, let’s dive deeper into what sets the harmonic balancer and crankshaft pulley apart:

- Harmonic Balancer

This part is primarily focused on reducing vibrations. It has a special design helps absorb and dampen the vibrations that occur when your engine starts and runs. Without the harmonic balancer, your engine might shake a lot more.

- Crankshaft Pulley

In contrast, the crankshaft pulley is more about mechanical work. It’s designed to turn things efficiently, ensuring that essential components in your car receive the power they need. It drives the alternator, power steering pump, and air conditioning compressor, allowing them to perform their functions.

Key Differences Between the Two

- Job: The most significant difference between the two is their primary function. The crankshaft pulley is responsible for turning various car accessories, while the harmonic balancer focuses on minimizing engine vibrations.

- Location: You’ll usually find the crankshaft pulley at the front of the engine, near the belts and accessories it powers. The harmonic balancer, however, is generally closer to the engine’s center.

- Design: These parts also differ in design. The crankshaft pulley typically has a straightforward design with grooves or notches to accommodate belts, while the harmonic balancer may incorporate rubber or other materials to absorb vibrations.

- Importance: Both the crankshaft pulley and harmonic balancer are crucial for your car’s overall performance and longevity. If the crankshaft pulley fails, essential accessories may stop working correctly. On the other hand, if the harmonic balancer malfunctions, it can affect your engine’s health and potentially lead to more significant issues.

While the crankshaft pulley and harmonic balancer may seem similar at first glance, they serve distinct roles in your car’s operation. The crankshaft pulley keeps accessories running smoothly, while the harmonic balancer ensures your engine runs as smoothly as possible by absorbing vibrations. Understanding these differences can help you appreciate the complexity of your vehicle’s engine and the critical functions these components perform.

Conclusion

The crankshaft pulley and harmonic balancer may appear as inconspicuous components, but their roles are far from minor. These two elements work tirelessly within your car’s engine, ensuring its smooth operation and longevity.

The crankshaft pulley, our engine’s power transmitter, turns the gears of vital accessories such as the alternator, power steering, and air conditioning compressor. Its impeccable functioning is key to keeping these essential parts running efficiently.

In contrast, the harmonic balancer plays a quieter yet equally critical role as an engine stabilizer. It absorbs and dampens the vibrations generated during engine operation, preventing excessive shaking and ensuring a smoother ride.

While both components share the same stage, they have distinct functions. The crankshaft pulley is all about mechanical work, while the harmonic balancer minimizes vibrations. Understanding these differences allows you to appreciate the intricacies of your vehicle’s engine.

As you embark on your automotive journey, armed with knowledge about these components, you’re better equipped to maintain your car’s health. Whether it’s the replacement of a crankshaft pulley or ensuring the harmonic balancer’s optimal performance, your awareness of their roles will prove invaluable.

So, the next time you lift the hood of your car, remember the unassuming heroes—the crankshaft pulley and harmonic balancer—working diligently to keep your vehicle running smoothly. In the intricate dance of engine components, they play their parts to perfection, ensuring your car’s reliability and performance on the open road.