Air Suspension Not Airing Up is a common issue faced by many vehicle owners.

This problem can lead to a rough ride, decreased fuel efficiency, and potential damage to the vehicle’s undercarriage.

Understanding why this happens, how to diagnose the problem, and what steps to take to fix it can save you time, money, and unnecessary stress.

In this article, we will delve into these aspects, providing you with practical knowledge and actionable solutions.

What are the 4 common air suspension system problems?

-

Air Compressor Failure

The air compressor is a vital part of the air suspension system. It’s responsible for pumping air into the air springs, ensuring that the vehicle maintains an optimal ride height. However, like any mechanical component, it can wear out over time due to continuous use, poor maintenance, or exposure to harsh environmental conditions. When the air compressor fails, it can no longer supply the necessary air pressure to the system. This failure can lead to the air suspension not airing up, resulting in a rough ride and potential damage to the vehicle’s undercarriage.

-

Airbag or Air Strut Leaks

Airbags or air struts are key components of the air suspension system. They inflate and deflate as needed to adjust the vehicle’s ride height. However, these components can develop leaks due to wear and tear, damage, or manufacturing defects. When this happens, the air suspension system may not air up properly, causing the vehicle to sag or not maintain the correct ride height. This can affect the vehicle’s handling, ride comfort, and fuel efficiency.

-

Electronic Malfunctions

The air suspension system relies heavily on electronic components, including sensors and control modules. These components monitor and control the operation of the system, ensuring that it functions correctly. However, these electronic components can malfunction due to various reasons, such as electrical shorts, software issues, or component failures. When this happens, it can lead to problems with the air suspension system, including the system not airing up.

-

Air Dryer Problems

The air dryer is an often overlooked but essential component of the air suspension system. It removes moisture from the air before it enters the system. This is crucial because moisture can cause corrosion and other damage to various components of the air suspension system. If the air dryer fails, it can allow moisture to enter the system, potentially leading to various problems, including the air suspension not airing up.

Why is my air suspension not working?

There could be several reasons why your air suspension is not working. It could be due to a failure in the air compressor, which is responsible for pumping air into the system. If it’s worn out or damaged, it may not provide the necessary air pressure.

Another common issue is leaks in the airbags or air struts. These leaks can cause the vehicle to sag or fail to maintain the proper ride height.

Electronic malfunctions in sensors and control modules can also cause the system to fail. These components are crucial for monitoring and controlling the operation of the system.

Lastly, problems with the air dryer can lead to issues. The air dryer removes moisture from the air before it enters the system. If it fails, moisture can cause damage to various components of the air suspension system.

In each of these cases, prompt diagnosis and repair are essential to prevent further damage and ensure the smooth operation of your vehicle. In the following sections, we will discuss how to diagnose and fix these issues.

Air suspension not airing up in Mercedes: What could be the reasons and solutions?

![[SOLVED] Air Suspension Not Airing Up: Why & Quick Solutions!](https://i0.wp.com/carfixexperts.com/wp-content/uploads/2023/12/SBF_air_suspension_air_compressor.webp?resize=518%2C345&ssl=1)

The reasons are similar to the ones we discussed above.

Air suspension not airing up in Ford: What to do?

The reasons are similar to the ones we discussed above.

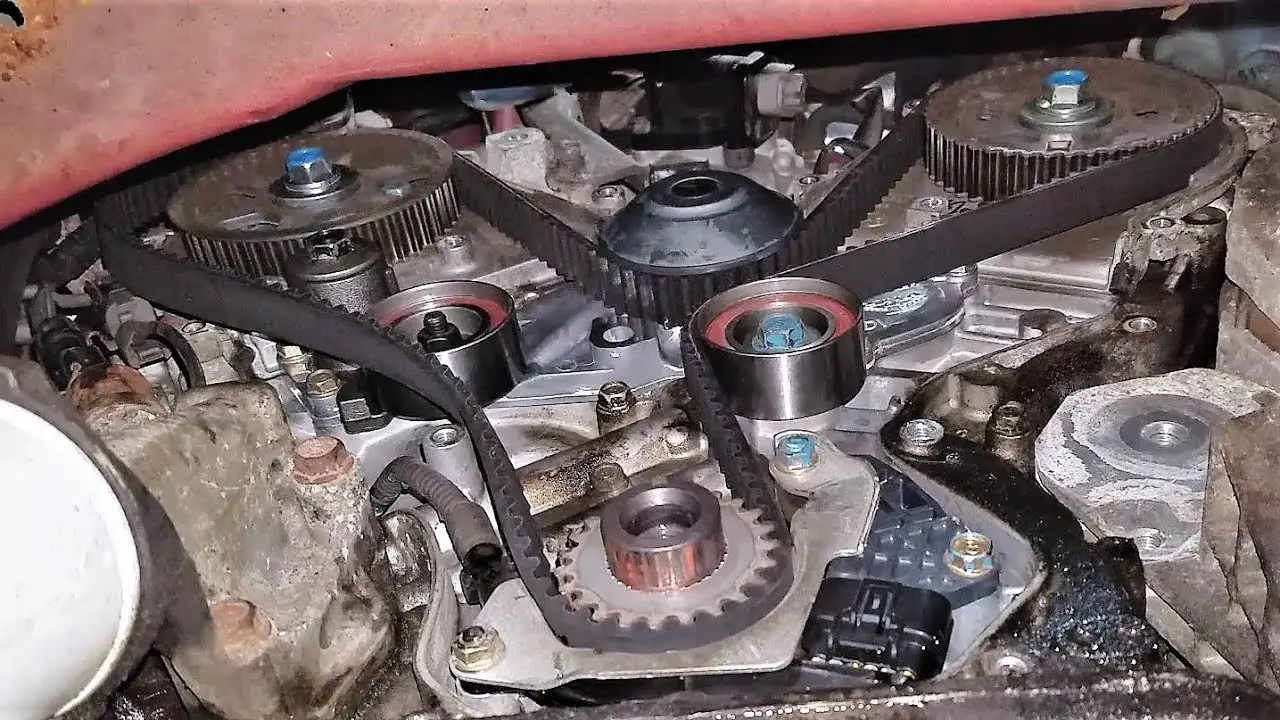

Where is the air suspension air compressor located?

The air suspension compressor is typically located in the engine compartment or under the vehicle. The exact location can vary depending on the vehicle model.

For instance, in some vehicles, you might find the air compressor right behind the front bumper, underneath the headlight on the passenger side.

In others, it could be located approximately under the right front door hinges, in the free room above the plastic bottom trim, under the car floor.

It’s always best to refer to your vehicle’s manual or consult a professional mechanic for the exact location in your specific vehicle.

This information is crucial as the compressor plays a key role in the functioning of the air suspension system.

How do I know if my air suspension compressor is bad?

Knowing if your air suspension compressor is bad can be determined by observing several signs:

-

Vehicle Sagging

If your vehicle is sagging or lower than usual, particularly on one side, it could be a sign of a bad air suspension compressor. The compressor is responsible for maintaining the correct pressure in the air suspension system. If it’s not working correctly, it can’t inflate the air springs to the proper level, leading to sagging.

-

Noisy Operation

A properly functioning air suspension compressor should operate relatively quietly. If you notice excessive noise when the compressor is running, it could be a sign that it’s failing.

-

Inability to Adjust Ride Height

One of the benefits of an air suspension system is the ability to adjust the ride height. If you find that you’re unable to raise or lower your vehicle, it could be due to a bad compressor.

-

Warning Lights

Many vehicles with air suspension systems have warning lights on the dashboard that illuminate when there’s a problem with the system. If this light comes on, it could indicate a problem with the compressor.

-

Poor Ride Quality

If your vehicle’s ride quality has deteriorated, with excessive bouncing or stiffness, it could be due to a failing air suspension compressor.

What happens when the air suspension compressor is not turning on?

When the air suspension compressor is not turning on, it can lead to several issues:

-

Vehicle Sagging or Lowering

The air suspension compressor is responsible for inflating the air springs to the correct pressure. If the compressor isn’t turning on, it can’t inflate the air springs, leading to the vehicle sagging or lowering.

-

Poor Ride Quality

The air suspension system plays a crucial role in maintaining the ride quality of the vehicle. If the compressor isn’t working, the vehicle may experience a rougher ride due to the lack of proper suspension.

-

Inability to Adjust Ride Height

One of the advantages of an air suspension system is the ability to adjust the ride height. If the compressor isn’t turning on, you won’t be able to raise or lower the vehicle as needed.

-

Warning Lights

If the air suspension compressor isn’t turning on, it could trigger warning lights on the dashboard indicating a problem with the air suspension system.

How to check air suspension for leaks?

Checking your air suspension for leaks involves a few steps:

-

Visual Inspection

Start by visually inspecting the air springs and other components of the air suspension system. Look for signs of damage or wear that could cause a leak.

-

Listen for Leaks

Turn on your vehicle and listen carefully. A leaking air suspension system might produce a hissing sound as air escapes.

-

Soapy Water Test

This is a common method for detecting leaks. Spray soapy water on the air suspension components, especially around the air springs and the connections. If there’s a leak, you’ll see bubbles forming at the leak point due to the escaping air.

-

Ride Height Sensor Check

If your vehicle is equipped with ride height sensors, check if the vehicle is maintaining its ride height. If the vehicle sags or lowers after being parked for a while, it could indicate a leak in the system.

-

Professional Inspection

If you’re unable to find the leak or if the leak is in a hard-to-reach area, it may be best to have a professional mechanic inspect the system. They have specialized tools and experience to accurately locate and fix air suspension leaks.

Can you fix air suspension leaks yourself?

Yes, it is possible to fix air suspension leaks yourself, but it depends on the severity of the leak and your level of mechanical skill. Minor leaks can often be fixed with a sealant that is specifically designed for air suspension systems. This involves injecting the sealant into the system, where it will find and seal small leaks.

However, larger leaks or leaks in certain components, like the air compressor or electronic parts, may require part replacement. In these cases, or if you’re not comfortable doing the repair yourself, it’s best to take your vehicle to a professional mechanic.

Remember, while fixing minor leaks can be a DIY job, air suspension systems are complex. Incorrect repairs can lead to further damage or even safety issues. Always consult with a professional if you’re unsure.

What is air suspension sealant and how can it help?

Air suspension sealant is a product designed to seal small leaks in the air suspension system.

It works by being injected into the system, where it circulates and fills in small holes or cracks that are causing air to escape.

The sealant can be a quick and cost-effective solution for minor leaks.

However, it’s important to note that it’s not a permanent fix and may not be effective for larger leaks or damage.

Moreover, while it can help in some situations, using a sealant should not replace regular maintenance and inspections of your air suspension system.

Always consult with a professional if you’re unsure or if the problem persists after using a sealant.

It’s crucial to ensure the proper functioning of your air suspension system for the comfort and safety of your ride.

What is the typical air suspension leak repair cost?

The cost of repairing an air suspension leak can vary widely depending on the severity of the leak and the make and model of your vehicle.

If you need an airbag replaced, for example, this can cost upwards of $1,000 once you include parts and labor.

However, for a full-scale suspension system repair, you should expect to pay around $3,200 on average.

The typical price range for such a repair would be anywhere between $1,100 and $5,200.

Please note that these are just estimates and the actual cost can vary.

It’s always best to get a quote from a professional mechanic for an accurate estimate.

Where does air come from for air suspension?

The air for an air suspension system comes from the atmosphere.

The system’s air compressor draws in outside air, compresses it, and then sends it to the air springs.

The air compressor is a crucial component of the air suspension system, and it’s typically powered by the vehicle’s engine or an independent electric motor.

The compressed air is what allows the air springs to adjust the vehicle’s ride height and absorb road shocks, providing a smooth and comfortable ride.

It’s important to note that the air compressor, air springs, and other components of the air suspension system need to be properly maintained to ensure optimal performance.

What controls the air suspension?

The air suspension system is controlled by a combination of mechanical and electronic components. The main components include:

-

Air Compressor

This component draws in outside air, compresses it, and sends it to the air springs.

-

Air Springs

These are inflatable rubber devices that replace conventional springs. They adjust to varying loads and road conditions by inflating or deflating.

-

Height Sensors

These sensors measure the distance between the axle and the chassis. They send this information to the control module.

-

Control Module

This is the brain of the air suspension system. It receives information from the height sensors and other inputs, and then controls the air compressor and air spring solenoids to adjust the ride height and firmness.

-

Solenoid Valves

These are electrically controlled valves that control the air flow into and out of the air springs.

-

Air Lines

These are the tubes that carry compressed air from the compressor to the air springs.

How do you adjust air suspension for optimal performance?

Adjusting an air suspension system for optimal performance involves several steps:

-

Understand Your System

First, familiarize yourself with your vehicle’s air suspension system. Read the owner’s manual or consult with a professional to understand how the system works and how it can be adjusted.

-

Check the System

Regularly check the air suspension components for any signs of damage or wear. This includes the air springs, air lines, and air compressor. Also, ensure that the system is free of leaks.

-

Adjust the Ride Height

Most air suspension systems allow you to adjust the ride height. This can be done through the vehicle’s onboard controls or a separate controller, depending on the system. Adjust the ride height according to your driving conditions for optimal performance and comfort.

-

Maintain Proper Pressure

Ensure that the air springs are inflated to the manufacturer’s recommended pressure. Over or under-inflation can affect the system’s performance and may cause damage.

-

Professional Servicing

Have the system professionally serviced at regular intervals. This will ensure that all components are in good working order and can help identify potential issues before they become major problems.

Also Read: How To Stop Seat Belt From Tightening: All You Need To Know!

FAQs – Air Suspension Not Airing Up

What is the lifespan of an air suspension system?

The lifespan of an air suspension system can vary greatly depending on the vehicle make and model, the quality of the components, and how well the system is maintained. On average, parts of the system like the air compressor or the air springs might need to be replaced every 50,000 to 70,000 miles. However, with proper care and maintenance, the system can last much longer.

Can I replace the air suspension system with a traditional coil spring system?

Yes, it’s possible to replace an air suspension system with a traditional coil spring system. This is known as a conversion kit and can be a cost-effective solution if the air suspension system is frequently failing. However, it’s important to note that you may notice a difference in ride quality and handling as coil springs can’t adjust to load or road conditions like an air suspension can.

Does driving with a failing air suspension system cause damage to my vehicle?

Driving with a failing air suspension system can potentially cause damage to your vehicle. The system is designed to absorb road shocks and adjust the vehicle’s ride height. If it’s not working properly, it can put more strain on other components of the vehicle and lead to a rougher ride. It’s recommended to have the system repaired as soon as possible if it’s failing.

How does temperature affect the air suspension system?

Extreme temperatures can affect the air suspension system. Cold temperatures can cause the air inside the system to contract, which might result in the vehicle sitting lower than usual. On the other hand, high temperatures can cause the air to expand, potentially leading to a higher ride height. Most modern air suspension systems are designed to compensate for these temperature effects to maintain a consistent ride height.

What are the benefits of an air suspension system?

Air suspension systems offer several benefits. They provide a smoother ride compared to traditional spring suspension systems, as they can adjust to different road conditions and vehicle loads. They also allow for adjustable ride height, which can be beneficial for different driving conditions. Plus, they can provide better handling and fuel efficiency.

Are air suspension systems more expensive to maintain?

Air suspension systems can be more expensive to maintain compared to traditional spring suspension systems. This is because they have more components that can fail or wear out, such as the air compressor, air springs, and electronic sensors. However, the improved ride quality and handling they provide can be worth the extra maintenance cost for many drivers.

Can I install an air suspension system in a vehicle that didn’t originally come with one?

Yes, it’s possible to install an air suspension system in a vehicle that didn’t originally come with one. This is known as an aftermarket air suspension kit. It’s a complex process that involves replacing the existing suspension system and should be done by a professional. It’s also important to note that installing an aftermarket kit might void the vehicle’s warranty.

Does an air suspension system improve fuel efficiency?

Yes, an air suspension system can potentially improve fuel efficiency. By maintaining optimal ride height and reducing drag, it can enhance the vehicle’s aerodynamics, which can lead to better fuel efficiency. However, the actual impact on fuel efficiency can vary depending on the vehicle model and driving conditions.

Is it safe to drive with a malfunctioning air suspension system?

While it might not be immediately dangerous to drive with a malfunctioning air suspension system, it’s not recommended. A failing air suspension can affect the vehicle’s handling and braking, potentially making it unsafe. It can also lead to other parts of the vehicle wearing out more quickly. If your air suspension system is not working properly, it’s best to have it inspected and repaired as soon as possible.

What is the difference between air suspension and hydraulic suspension?

Air suspension uses air to adjust the vehicle’s ride height and comfort, while hydraulic suspension uses a liquid hydraulic fluid. Air suspension systems are generally more flexible and can offer better ride comfort and load capacity. On the other hand, hydraulic systems can provide better handling and performance, but they can be more complex and expensive to maintain.

Conclusion – Air Suspension Not Airing Up

Understanding what Air Suspension Not Airing Up is can significantly enhance your vehicle’s performance and longevity.

From recognizing common air suspension problems to knowing how to check for leaks and understanding the role of the air compressor, every aspect plays a crucial role.

Whether you drive a Mercedes, a Ford, or any other vehicle with an air suspension system, being informed about potential issues and their solutions can save you time, money, and unnecessary stress.

Remember, regular maintenance and timely repairs are key to keeping your air suspension system in optimal condition.

Safe and smooth driving to you!

![[SOLVED] Air Suspension Not Airing Up: Why & Quick Solutions!](https://carfixexperts.com/wp-content/uploads/2023/12/ventilated-disk-brakes-air-suspension-260nw-188303348-e1701732083676.webp)