Discovering that your 4L80 transmission has lost its reverse gear can be a daunting experience.

This issue is not just inconvenient but can signal significant underlying problems.

If you’re facing the dreaded “4L80 transmission no reverse” scenario, don’t despair.

In this article, we’ll guide you through the essential steps to diagnose and address this perplexing issue.

With a focus on simplicity and clarity, we aim to empower you with the knowledge to tackle this challenge head-on.

Stay tuned as we delve into the world of transmission troubleshooting, ensuring your journey back to full functionality is as smooth as possible.

Why Has My 4L80 Transmission Lost Reverse?

The loss of reverse in a 4L80 transmission can be a perplexing issue, but understanding the common causes can help pinpoint the problem. They include:

-

Hydraulic Issues

The 4L80 transmission relies on hydraulic pressure to engage gears. If there’s a leak or blockage in the hydraulic circuits, it can prevent the reverse gear from engaging. This could be due to a faulty valve body, which directs the hydraulic fluid, or issues with the seals and gaskets that maintain pressure.

-

Mechanical Failures

Mechanical components like the reverse band or direct clutch, which are crucial for engaging reverse, could be worn or damaged. The reverse band wraps around parts of the gear train and clamps down to engage reverse. If it’s worn out or the servo that operates it is malfunctioning, reverse won’t engage. Similarly, if the direct clutch is damaged, it can’t hold the necessary components stationary for reverse operation.

-

Electrical Problems

The 4L80 is controlled electronically, which means solenoids and sensors play a part in gear selection. If there’s an electrical fault, like a failed solenoid or a bad connection, the transmission might not receive the command to engage reverse.

-

Oil Contamination

Transmission fluid is the lifeblood of the system, and if it’s contaminated, it can cause all sorts of issues, including the loss of reverse. Contaminated fluid can lead to wear and tear on the valve body, bands, and clutches.

-

Wear and Tear

Over time, the internal components of the transmission experience wear and tear. This natural degradation can lead to a failure of parts that are essential for the reverse gear’s operation.

Important: Is The 2019 GMC Sierra 3500HD Denali Dually 6.6L Duramax Diesel Right For You?

What Are The Common Causes Of No Reverse In A 4L80 Transmission?

The “No Reverse” issue in a 4L80 transmission can be attributed to several factors, each affecting the transmission’s ability to engage the reverse gear. These are the common causes:

-

Hydraulic Failures

The 4L80 transmission depends on precise hydraulic pressure to function. If there’s a leak or obstruction in the hydraulic system, it can result in insufficient pressure to engage the reverse gear. Problems with the valve body, which directs fluid flow, or with seals and gaskets that maintain pressure, are often to blame.

-

Mechanical Wear and Damage

Over time, the mechanical components such as the reverse band or the direct clutch can wear out or become damaged. The reverse band is responsible for engaging the reverse gear, and if it or the servo that controls it fails, the reverse will not engage. Similarly, if the direct clutch is compromised, it won’t be able to perform its role in reverse gear selection.

-

Electrical and Sensor Issues

The 4L80 is an electronically controlled transmission, meaning solenoids and sensors are integral to its operation. Faulty solenoids, wiring issues, or sensor failures can disrupt the signals required to engage the reverse gear.

-

Contaminated Transmission Fluid

Transmission fluid quality is vital for the proper operation of all gears, including reverse. Contaminated or degraded fluid can lead to increased wear on the valve body, bands, and clutches, which can cause the reverse gear to fail.

-

Component Breakage

Rare but possible, a broken intermediate sun gear shaft or other critical component can lead to a loss of reverse. Such breakages prevent the necessary engagement of the planetary gear set required for the reverse gear.

How Can I Diagnose The ‘no Reverse’ Issue In My 4L80?

Diagnosing the ‘no reverse’ issue in a 4L80 transmission involves a systematic approach to identify whether the problem is hydraulic, mechanical, or electrical. Here’s a step-by-step guide to help you pinpoint the issue:

-

Check Transmission Fluid

Ensure the transmission fluid is at the correct level and in good condition. Low or dirty fluid can cause loss of reverse.

-

Inspect for Hydraulic Issues

Perform a line pressure test to check if the hydraulic pressure is within the specification for reverse gear.

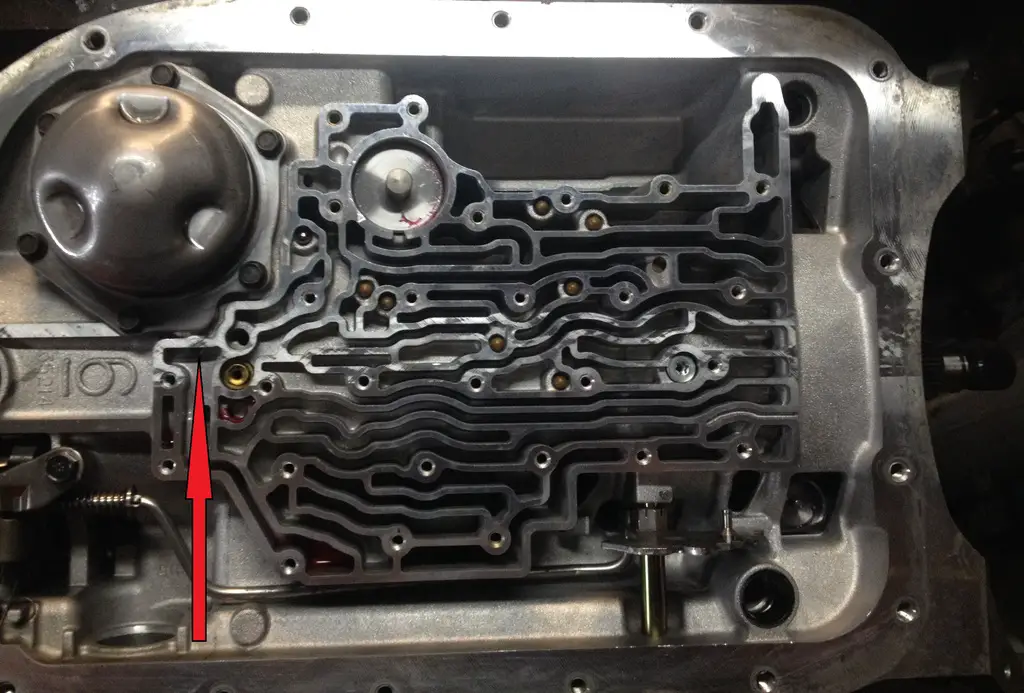

Examine the valve body for any signs of wear or damage that could affect fluid flow.

-

Evaluate Mechanical Components

Inspect the reverse band and direct clutch for wear or damage. These components are crucial for engaging the reverse gear.

Look for any broken parts, such as the intermediate sun gear shaft, which can prevent reverse engagement.

-

Assess Electrical System

Test the electrical solenoids and sensors that control the reverse gear engagement. Faulty solenoids or wiring issues can lead to loss of reverse.

Use a diagnostic scanner to check for any transmission-related error codes.

-

Road Test

Conduct a road test to observe the transmission’s behavior in different gears. This can help determine if the issue is isolated to reverse gear.

Is There A Quick Fix For A 4L80 Transmission Without Reverse?

While there’s no guaranteed “quick fix” for a 4L80 transmission with no reverse, some temporary solutions have been suggested by mechanics and enthusiasts. These are not permanent repairs and should be approached with caution:

Adjusting the Servo Piston Rod

Some have found that lengthening the servo piston rod can temporarily increase pressure on the reverse band, allowing it to engage.

Checking Electrical Connections

Ensuring all electrical connections, especially to solenoids, are secure and functioning can sometimes resolve simple reverse issues.

Fluid and Filter Change

A fresh fluid change and new filter can sometimes improve transmission performance if the issue is related to contamination or clogs.

What Should I Avoid Doing When My 4L80 Loses Reverse?

When your 4L80 transmission loses reverse, it’s crucial to avoid actions that could exacerbate the issue or cause further damage. This is what to steer clear of:

-

Do Not Continue Driving

Avoid driving the vehicle if possible. Driving with a malfunctioning transmission can lead to more extensive damage.

-

Avoid Quick Fixes

Resist the temptation to try quick fixes or adjustments without proper diagnosis. These can often lead to more significant problems or mask the underlying issue.

-

Don’t Ignore Warning Signs

If you notice unusual noises, smells, or behavior from your transmission, don’t ignore them. These could be signs of bigger problems.

-

Don’t Force the Gear

Never force the transmission into reverse. This can cause further mechanical damage.

-

Avoid Excessive Revving

High engine revs can put additional stress on the transmission components, potentially causing more harm.

-

Skip DIY If Unsure

If you’re not confident in your mechanical skills, avoid attempting to diagnose or repair the issue yourself. Incorrect handling can worsen the situation.

-

Don’t Delay Professional Help

Postponing a professional inspection and repair can turn a potentially minor repair into a major one.

Can Regular Maintenance Prevent Reverse Failure In 4L80 Transmissions?

Regular maintenance is key to the longevity and reliability of any transmission, including the 4L80. While it may not prevent every instance of reverse failure, it significantly reduces the risk.

-

Transmission Fluid Checks

Regularly checking and maintaining the correct fluid level is crucial. The fluid lubricates, cools, and cleans internal components. It also transmits hydraulic power. Low or dirty fluid can lead to premature wear and failure.

-

Fluid and Filter Changes

Changing the transmission fluid and filter according to the manufacturer’s recommendations helps remove contaminants that can cause wear and damage to the transmission’s internal parts.

-

Band Adjustments

The reverse band in the 4L80 transmission may require periodic adjustments. Properly adjusted bands ensure the correct engagement of gears and help prevent slippage and wear.

-

Regular Inspections

Frequent inspections can catch issues like leaks, wear, and electrical problems before they lead to a loss of reverse. A professional can spot early signs of trouble that you might miss.

-

Software Updates

For electronically controlled transmissions like the 4L80, keeping the software up to date is important. Manufacturers may release updates that improve the function and longevity of the transmission.

-

Avoiding Harsh Driving

Harsh driving conditions and habits can stress the transmission. Regular maintenance combined with smooth driving can extend the life of the transmission.

What Are My Options If My 4L80 Transmission Won’t Go In Reverse?

If your 4L80 transmission won’t go in reverse, you have several options to consider for addressing the issue. This includes:

-

Professional Diagnostic

The first step is to get a professional diagnostic to accurately identify the cause of the problem. This may involve checking the transmission fluid, hydraulic pressures, mechanical components, and electrical systems.

-

Hydraulic Repairs

If the issue is hydraulic, such as a leak or blockage, repairs might involve replacing seals, gaskets, or the valve body.

-

Mechanical Repairs

Mechanical issues, like a worn reverse band or damaged direct clutch, will require replacement or adjustment of the affected parts.

-

Electrical Repairs

Electrical problems may need troubleshooting and replacement of faulty solenoids, sensors, or wiring.

-

Transmission Fluid Service

Sometimes, a simple transmission fluid change can resolve the issue if it’s related to dirty or degraded fluid.

-

Adjustments

Certain adjustments, such as the servo piston rod length, can sometimes temporarily restore reverse functionality.

-

Rebuild or Replacement

In cases where the transmission has significant damage or wear, a complete rebuild or replacement might be necessary.

-

Aftermarket Upgrades

For those looking to not only fix the issue but also improve performance, aftermarket parts and upgrades can be considered.

What Are The Common Problems With A 4L80E Transmission?

The 4L80E transmission, known for its durability and use in heavy-duty applications, does have its share of common issues. These are the problems often reported by users and mechanics:

Overheating: One of the most frequent problems with the 4L80E is overheating. This can be caused by heavy towing, insufficient cooling, or aggressive driving habits. Overheating can lead to fluid breakdown, which in turn causes more internal damage.

Pump Failure: The transmission pump is responsible for circulating fluid throughout the system. Pump failures in the 4L80E can result in poor line pressure, leading to flared shifts and slippage.

Solenoid and Electrical Issues: Shift solenoids control the flow of hydraulic fluid for gear selection. Electrical problems can render these solenoids ineffective, leading to delayed or missed shifts.

Torque Converter Problems: Issues with the torque converter can cause a variety of symptoms, including shuddering, slipping, and even complete loss of power transfer from the engine to the transmission.

Clutch Wear: The clutches in the 4L80E can wear prematurely, especially under high-stress conditions. Worn clutches will lead to slippage and can eventually result in the transmission not being able to engage certain gears.

Planetary Gear Failure: The planetary gears allow for the different gear ratios in the transmission. If these gears fail, it can lead to a loss of certain gears, unusual noises, and ultimately, transmission failure.

Valve Body Issues: The valve body acts as the control center for the transmission. Problems here can cause erratic shifting, delayed gear engagement, and can affect overall transmission performance.

Oil Starvation: Proper lubrication is vital for the transmission’s operation. Oil starvation, often due to leaks or low fluid levels, can cause significant damage to internal components.

What Controls The Shifting In A 4L80 Transmission?

The shifting in a 4L80E transmission is controlled by a sophisticated electronic system designed to ensure precise and efficient gear changes. These are the components involved:

Electronic Control Unit (ECU)

The ECU, also known as the Transmission Control Module (TCM), is the central processing unit for the transmission. It receives input from various sensors and uses this data to determine the optimal shift points.

Sensors

Key sensors provide the ECU with necessary information:

Throttle Position Sensor (TPS): Measures the throttle’s position and sends data to the ECU regarding engine load and the driver’s power demand.

Vehicle Speed Sensor (VSS): Monitors the vehicle’s speed, which helps the ECU decide when to shift gears.

Input and Output Speed Sensors: Measure the rotational speed of the input and output shafts, providing feedback on the transmission’s performance and gear ratios.

Shift Solenoids

These are electromechanical valves that control the flow of hydraulic fluid to the transmission’s clutches and bands. The ECU activates these solenoids to manage gear engagement and disengagement.

Torque Converter Clutch (TCC) Solenoid: This solenoid controls the lock-up mechanism of the torque converter, improving fuel efficiency by directly linking the engine to the transmission at cruising speeds.

Pressure Control Solenoid: Regulates the hydraulic pressure used for shifting, ensuring smooth transitions between gears.

Manual Valve

Operated by the gear selector, this valve directs fluid to different passages in the valve body to engage the desired gear.

What Controls A 4L80E Transmission?

The 4L80E transmission is controlled by an electronic system that includes the Powertrain Control Module (PCM), various sensors, and shift solenoids. The PCM is the main computer that uses input from sensors to manage the transmission’s shifting patterns. These sensors include the Throttle Position Sensor (TPS) and Vehicle Speed Sensor (VSS), which monitor the engine’s load and the vehicle’s speed. Shift solenoids are activated by the PCM to regulate the flow of hydraulic fluid for gear selection. Additionally, the Torque Converter Clutch (TCC) solenoid controls the lock-up mechanism of the torque converter for improved fuel efficiency.

What Is The Difference Between 4L80 And 4L80E?

The primary difference between the 4L80 and 4L80E transmissions lies in their control systems. The 4L80 is a non-electronic transmission that relies on a mechanical control system, while the 4L80E includes electronic controls. The ‘E’ in 4L80E stands for ‘electronic’, indicating that it uses electronic solenoids for shifting gears instead of the hydraulic governor and throttle cable used in the 4L80. Additionally, the 4L80E features upgrades like an overdrive gear, a lock-up torque converter, and can handle more power and torque compared to the 4L80.

Conclusion

Facing a “4L80 transmission no reverse” issue can be a stressful ordeal, but it’s not insurmountable.

With the insights and guidance provided, you’re now equipped to approach the problem methodically.

Remember, the key is to diagnose accurately, act promptly, and seek professional assistance when needed.

Regular maintenance can ward off many troubles, but if reverse failure strikes, tackle it head-on with the knowledge that solutions are within reach.

Your 4L80 is a robust companion, and with the right care, it will continue to serve you reliably on the road ahead.

Drive safe, and keep your transmission in check!